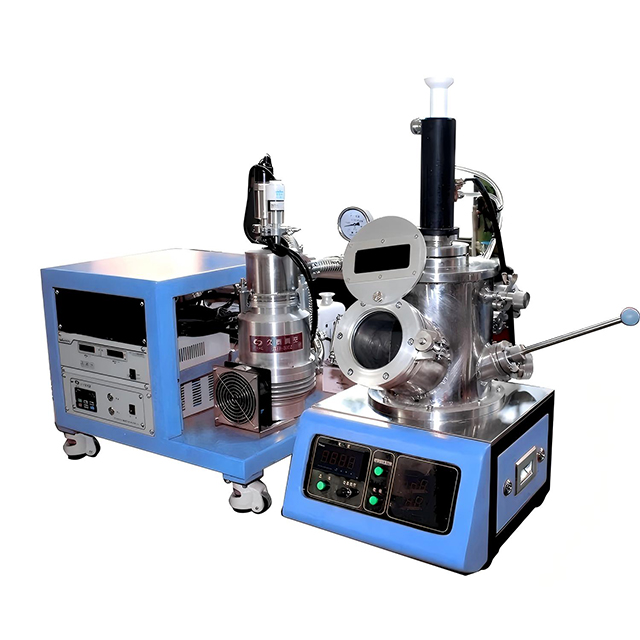

Components of well-type vacuum molybdenum wire sintering furnace KS-WT-VMB80

Structure and function description

Stove cover

The furnace cover adopts double-layer stainless steel (SUS304) water sandwich plate structure, which is assembled and welded into a whole with the flange. The inner wall is precisely polished and the outer wall is brushed. The furnace door is equipped with cooling water inlet and outlet, distillation collection device interface, furnace cover lifting connection seat, etc. The integrated design of the three-zone distillation collection device and the furnace cover makes it easy to take materials.

Furnace

The furnace body adopts a double-layer stainless steel (SUS304) water sandwich structure, which is assembled and welded with the upper and lower flanges to form a cylindrical structure. The upper flange is provided with a dovetail sealing groove and is sealed with an O-shaped silicone rubber sealing ring. The inner wall of the furnace is precisely polished and the outer wall is brushed. The side of the furnace body is equipped with cooling water inlet and outlet, vacuum exhaust port, thermocouple installation port, etc.

| Power supply | three-phase 380V 50Hz |

| Heating power | 12Kw |

| Design temperature | 1200℃ |

| Use temperature 1100℃ |

|

| Temperature control accuracy | ±1℃ |

| Temperature control zone | Zone 1 |

| Capacity | 1kg |

| Crucible size | ¢80*80 |

| Furnace pot size | ¢400*400mm (subject to actual design) |

| Temperature control method | K-type thermocouple |

| Temperature control accuracy | ±1℃ |

| Cold state ultimate vacuum | 6.7*10-4Pa (empty furnace, cold state, after baking and degassing) |

| Pressure rise rate | 4Pa/h |

| Inflation pressure | ≤0.05MPa |

| Control method | touch screen + plc |