Product Description:

KS-VF-MSP500 is a lab-scale vacuum melt spinning system for preparing amorphous metallic ribbons. In this technique, metal ingots (<50g) are melted via the induction heating method and then propelled by overpressurizing the crucible. A thin stream of molten is then dropped onto a fast-moving surface of a scold copper drum. This causes rapid quenching & solidification of the molten and thus forms the liquid metal alloy. One extra swingable induction coil is included in the vacuum chamber to make the melting casting sample small ingot ( < 500 g)

Technical Parameters:

Features

| · The complete system consists of the stainless steel vacuum chamber, turbo & mechanical pumps, 25KW induction heating system, rack system, and one meter long discharging tubular collector · 300mm diameter copper flywheel with max. 45 meter /sec. spinning speed · Lab-scale system for melting metallic samples up to 50 grams per batch (material melting point < 1000°C) · Crucible to copper wheel distance adjustable 0~10mm (manual adjustment) · TC insert to the bottom of the crucible can measure the temperature above the melt (direct contact between the TC and melt should be avoided) · Featured a position adjustable "scraper" can prevent ribbon spin-off to the inside of the chamber · Vacuum casting attachment is optional as a great add-on feature of the melt spinning system. |

| Power Requirements | · Input Voltage: 220VAC, Three-Phase, 60Hz · Input Power: 25 KW (50A breaker required) |

Control Station

| · All functional controls in one panel: Temperature & induction power control, copper drum spinning speed & ON/OFF, Mechanical & Turbo Pump ON/OFF, solenoid valves for pump isolation and gas purging, Melt-Spinning ON/OFF · Combined digital vacuum display for gauge |

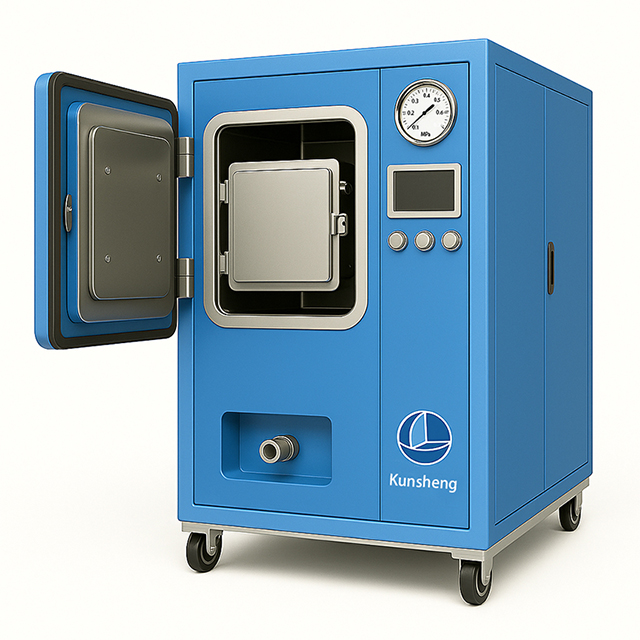

Vacuum Chamber & Pump

| · Stainless steel vacuum chamber: 400 W x 380 D x 600 H, mm,Hinged type door with quartz observation window (120mm dia.). · The extra coil is available for casting function is available upon request · Built-in turbo backed by the mechanical pump can pump down the chamber to 5 x10 E-5 torrs within 30 minutes |

Induction Heater

& Temperature Controller

| · Dual Station 25KW (30 - 80Khz) Induction Heater · Max. sample load: 10 - 50g for a loose sample and 100g max with pressed sample (based on NbFeB material) · A precision temperature controller is integrated with B type TC (24'' long) insert inside the heating crucible. (direct contact between the TC and melt should be avoided) · 30 segments temperature profile programmable with +/- 2°C accuracy |