Product Description:

Features of Vacuum Induction Spinning Furnace KS-VF-VMS20 Under high vacuum condition, the molten metal or alloy is sprayed onto the high-speed rotating copper roller, which is rapidly cooled to obtain a thin strip. Since this cooling rate is very fast, it can reach the order of 104K/s-106K/s, so that it can continue to maintain its liquid disordered structure during solidification, inhibit crystallization, and obtain amorphous piezoelectric materials. However, when the molten metal or alloy is cooled below the glass transition temperature, nucleation and crystallization will occur, and it is impossible to obtain a pressure-stable material.

Advantage

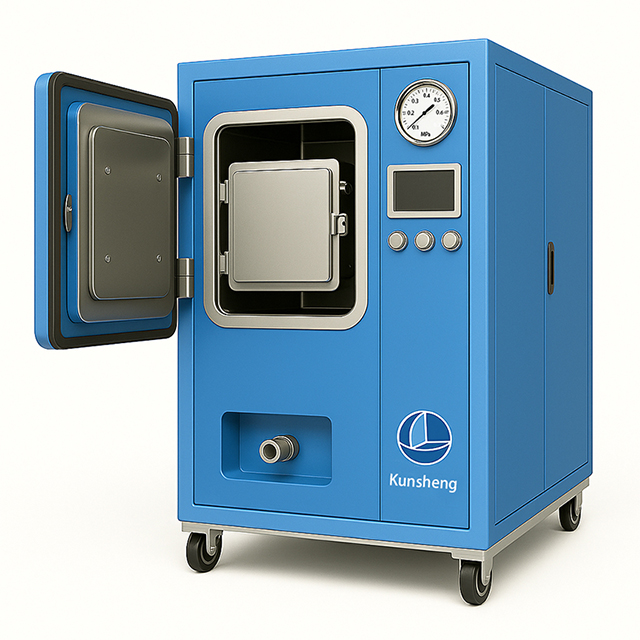

• Desktop design, small footprint, saving experimental space and energy • Small vacuum chamber for fast vacuuming, reliable dynamic sealing

• It can realize the functions of belt throwing and spray casting in the furnace. The crucible can be processed into various shapes according to customer requirements

·Customize spray parameters according to different materials ·Pressure gauge and valve to ensure safe vacuuming and argon filling

·Servo motor drives the copper rod, which can be adjusted steplessly and can display the speed in real time

typical application

Strip amorphous material was prepared by molten single roll spin quenching method, and bulk amorphous material was prepared by vacuum spray casting method. It is suitable for the scientific research of new materials in universities, research institutes and enterprises.

Technical Parameters:

| Model | KS-VF-VMS20 |

| Crucible capacity | 20g or Customized |

| Melting temperature | 300-2000C |

| Voltage | 380V,3 phase,50Hz |

| Total Power | 18Kw |

| Vacuum | 10ˉ² torr -10ˉ⁶ torr |

| Speed of Copper stick | 0-3000rpm |

| Stripe specification | 1-20mm adjustable |

| Control system | Touch screen |

| Casting function | Can produce 1mm-5mm diameter sample |

| Atmosphere gas | Nitrogen or Argon etc |