Equipment Use:

The vacuum hot pressing furnace combines vacuum/atmosphere, hot pressing and high temperature sintering, and is suitable for high temperature hot forming of new materials such as powder metallurgy and functional ceramics, such as transparent ceramics and industrial ceramics.

Vacuum sintering of porcelain and other metals and alloy materials composed of refractory metals and high-temperature sintering of ceramic materials silicon carbide and silicon nitride can also be used for powders or compacts below the melting point of the main component.

Heat treatment at temperature, the purpose is to improve the strength through metallurgical bonding between particles.

Equipment Composition:

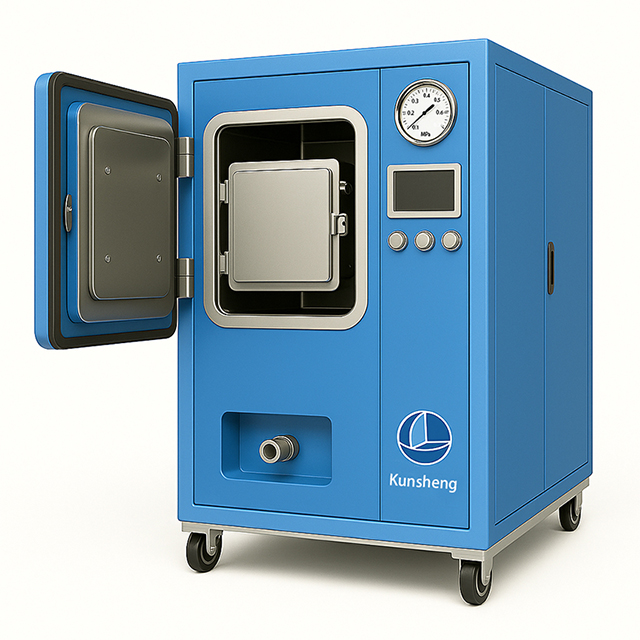

The furnace body is a vertical furnace shell, the inner layer is a cylinder made of stainless steel, and the outer layer is carbon steel. The furnace body is divided into two parts, one third of which is the furnace cover, which can be fully opened by hand, and the two thirds are solid.

Fixed furnace body, unique design, easy to operate. A jacket is formed between the two layers to pass the cooling water to take away the heat transferred to the furnace shell, so that the temperature of the furnace wall does not exceed 60℃, and the upper and lower flanges are welded into one overall. There are infrared temperature measurement holes (with protective atmosphere vents) in the middle, thermocouple temperature measurement holes, exhaust holes and observation holes. The platinum rhodium thermocouple has an automatic exit device when the temperature is reached, and the infrared temperature observation observation hole has the glass blowing anti-fog device, the observation hole used by the operator is equipped with a baffle.

Vacuum system: oil diffusion pump, roots pump, mechanical pump equipped with electromagnetic differential pressure valve (to prevent sudden power failure, mechanical pump oil backflow) inflation valve, air release valve, vacuum butterfly valve, vacuum pressure gauge (±Pa). It is composed of bellows, vacuum pipes and brackets.

Hydraulic system: Electric input mode is adopted. The hydraulic station is equipped with imported proportional valves, pressure sensors, displacement displays, grating rulers (ranging accuracy 0.02mm), hydraulic cylinders and other related hydraulic equipment.

The pressure adjustment is semi-automatic and can be adjusted manually. The instrument can be set to automatically adjust the pressure, and can achieve voltage stabilization and pressure maintenance.

Water cooling system: It is composed of various valve and pipeline related devices and is equipped with water-breaking sound and light alarm to automatically cut off the heating source or function.

Temperature control system: using thyristor to control temperature, equipped with PID function instrument, digital display, with over-temperature sound and light alarm function, can also choose PLC touch screen automatic control, and retain historical data, convenient analyze the sintering process.

Inflation system: It is composed of various pipes and valves, and is equipped with an electromagnetic deflation valve and pressure sensor. When the pressure in the furnace is higher than a safe value, it will automatically deflate. A needle valve is installed on the inflation pipeline to control the inflation air volume.