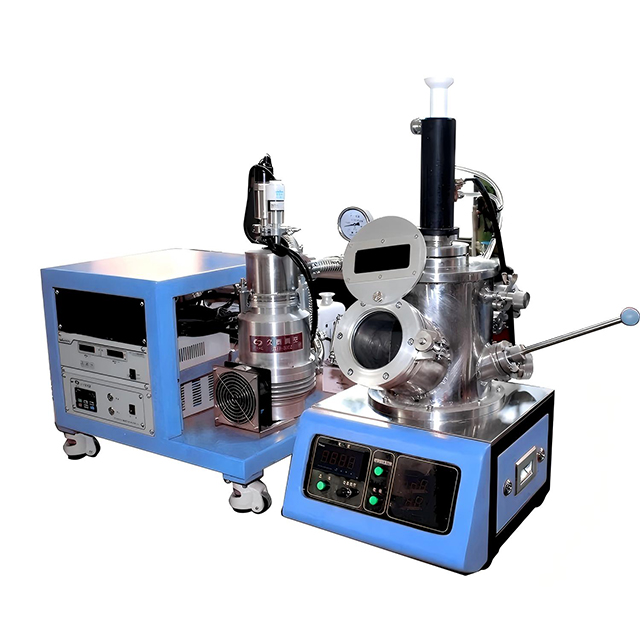

Product Description:

The mini vacuum arc melting furnace (Model: KS-VF-VAM20) is designed for melting high-melting-point metals, alloys, and for the preparation of bulk amorphous materials via vacuum suction casting. Compact and table-top in design, it is widely used in universities and research institutions for small-batch new material development under vacuum or inert atmosphere. It features a stainless steel structure, high vacuum capability, high-temperature arc melting up to 3500°C, and optional suction casting system.

Product Features:

1.Stainless steel vacuum chamber, compact and elegant structure.

2.Vertical side-opening chamber door and large observation window with filter glass.

3.Arc melting temperature over 3500°C with low power consumption.

4.Integrated cold-water chiller, plug-and-play operation.

5. 360° movable water-cooled copper electrode and replaceable crucibles.

6. Manual tilt pouring mechanism for uniform melt quality.

7. Built-in control panel with simulated interface for intuitive operation.

8. High vacuum design with quick pumping and low argon consumption.

9. Optional suction casting molds (e.g. 1, 1.5, 2, 4, 5 mm rods and flakes).

10. Can be placed inside gloveboxes for inert environment operation.

Technical Parameters:

| Model | KS-VF-VAM20 |

| Melting Capacity | 5–20 g |

| Max Arc Current | 250 A |

| Max Voltage | 20 V |

| Input Power | 6.3 KVA |

| Temperature Range | 0–3500℃ |

| Vacuum Level (cold state) | ≤ 5 Pa ~ 6.7×10⁻³ Pa |

| Electrode | Water-cooled, 360° movable |

| Crucible | Copper mold with 5× φ25 mm hemispherical cavities |

| Power Supply | 220V / 50Hz / single-phase |

| Dimensions | 350 × 450 × 650 mm |

| Weight | 60 kg |

| Installation Area | 1200 × 600 × 800 mm |