Product Description:

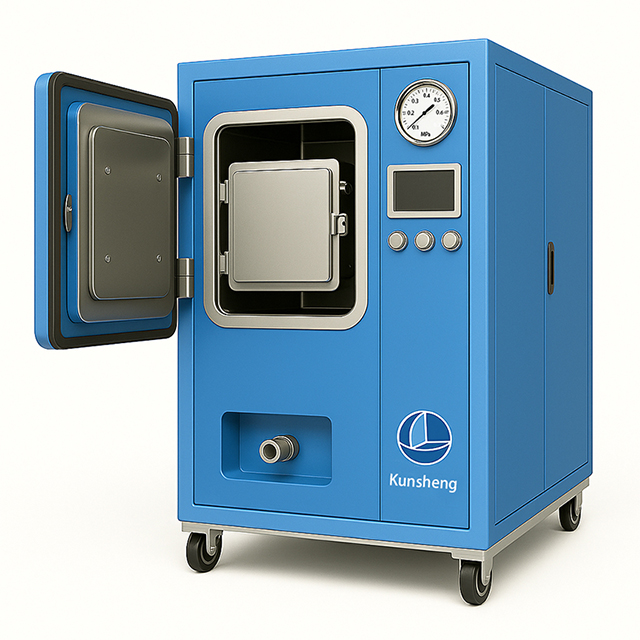

High vacuum single-roll rotary quenching system is used for induction melting and fast cooling belt forming of various metal materials under vacuum or atmosphere protection conditions; Suitable for the preparation of amorphous/microcrystalline thin strips or flakes of various materials. Experimental type using cold rolling quenching method to prepare thin sheet or thin strip amorphous material, this equipment is mainly composed of vacuum cavity, melting device, spraying device, throwing device, vacuum system, furnace support, electrical control system, water cooling system, etc.

Technical Parameters:

| Product model | High vacuum single-roll rotary quenching system KS-VF-MS-0.3 |

| Key features | Experimental type using cold rolling quenching method to prepare thin sheet or thin strip amorphous material, this equipment is mainly composed of vacuum cavity, melting device, spraying device, throwing device, vacuum system, furnace support, electrical control system, water cooling system, etc. |

| Technical parameters | 1. Each throwing belt, spraying alloy: 50g~300g2, each melting and casting alloy: 50~1000g3, high vacuum chamber vacuum: ≤5.0×10E-3Pa4, heating power supply: 25Kw; Frequency range: 30~80KHz5, can enter nitrogen, argon and other inert gases 6, copper roller diameter: 220mm, width: 40mm7, copper roller line speed: 5~70m/S8, water flow: 3~100L/min vacuum chamber is composed of furnace body, furnace cover and furnace bottom; The furnace body is welded by 304 stainless steel flange and inner and outer cylinder groups, the inner wall is mirror-polished, the furnace cover is processed by the overall solid 304, and a large-diameter observation window is opened on it, which can intuitively observe various experimental conditions in the furnace; The furnace door is machined from solid solid 304. Throwing device: It is composed of spray casting device, high-speed speed regulating motor, magnetic fluid sealing device and copper rod, etc., which can realize different copper rod line speeds by adjusting the motor speed. Vacuum system: composed of a molecular pump, a bipolar direct pump, three pneumatic baffle valves, vacuum pipeline and vacuum gauge, etc., the cold ultimate vacuum degree is better than 8.0×10E-5Pa. Furnace body bracket: It is assembled by profiles and steel plates, and the electric control cabinet adopts an integrated structure. The panel adopts analog screen, which can intuitively control various components of the equipment, and has water underpressure, water cut sound and light alarm and automatic cutting off heating function. Water cooling system: composed of water cooler, various valves and water pipes, etc., with electric contact water pressure gauge, with overpressure, undervoltage alarm function.

|