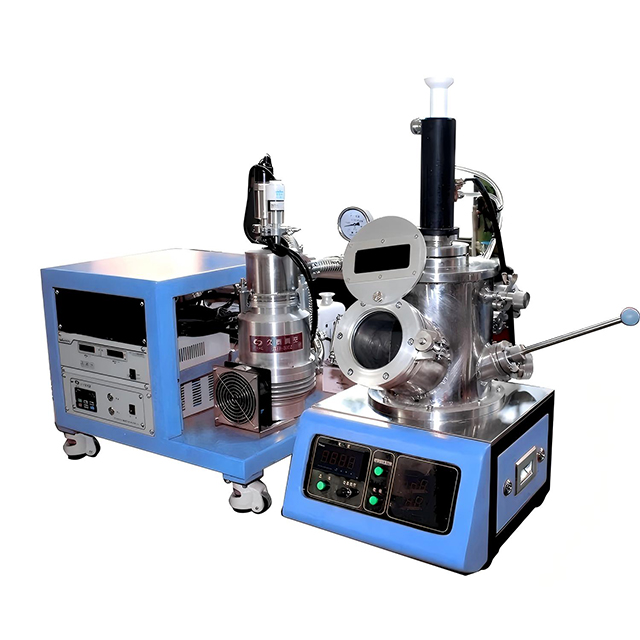

Vacuum induction melting furnace is also called vacuum melting casting furnace; it is specially designed and manufactured for industrial and research applications. Melting treatment, remelting and alloying, degassing and refining, homogenizing smelting, recycling, investment casting, precision casting, directional crystallization, single crystal growth

Features

■ The layout is reasonable and flexible, suitable for modular expansion or subsequent module supplementation/upgrade;

■ Alloying, sampling or other smelting operations in vacuum can be carried out through the vacuum sealing system;

■ Suitable for ingot casting, mold casting and precision casting ;

■ Convenient and safe control process cycle;

■ Wide pressure range from 10-5 Pa to 10Pa ;

■ The maximum melting temperature is greater than 2000 degrees

■ Manual or automatic control of melting and casting process (automatic pouring and casting) ;

■ Effective volume 0. 05 to 3 0 liters ( 50g - 2 00 kg).

■ Shorter vacuuming time and production cycle;

■ Increased process integrity and product quality through automatic casting control; reliability, durability, ease of maintenance.

Technical Parameters:

| Model | KS-HVF2000-400 |

| The total power of the equipment | 18KW |

| Power supply voltage | 380V, three-phase, 50Hz |

| Rated temperature | 300-2000℃ |

| Crucible capacity | 300-3000g (calculated as iron) |

| Coil configuration | 1 standard 1Kg coil, 1 3Kg coil |

| Vacuum chamber size | φ400*400mm |

| Ultimate vacuum | 5Pa——5*10E-4Pa (depending on the vacuum system) |

| 8. Protective atmosphere | nitrogen, argon ≤ 0.05MPa |

| 9. Weight of main unit | ~500Kg |

| 10. Optional | chiller, mechanical stirring device, infrared temperature measuring device, secondary feeding device, etc. |