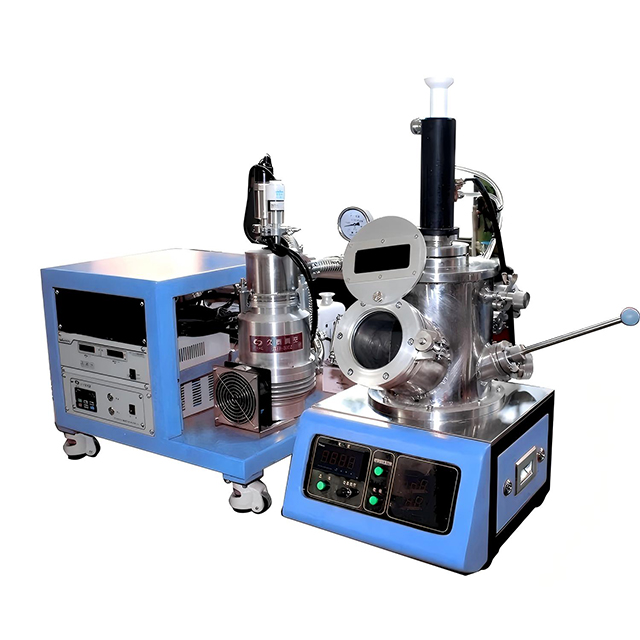

Brief description:

High vacuum annealing furnace, vacuum brazing furnace, vacuum heat treatment furnace is a cyclic operation type, specially used for vacuum reduction annealing and heat treatment of metal alloys and other materials, and can also be used for degreasing and dewaxing of metal metallurgical materials. It is widely used for vacuum heat treatment in stamping parts, beryllium copper, stainless steel, nickel copper, brass, copper, metal shrapnel, riveted parts, rivets, silver nodes, silver-copper composite parts, silver contacts, copper contacts and other fields.

Features of high vacuum annealing furnace, vacuum brazing furnace, vacuum heat treatment furnace

1. The vacuum annealing furnace is a vacuum airtight furnace tank and the heating wires are symmetrically distributed around it. The heating wires are embedded in ceramic fiber insulation materials and iron-chromium-aluminum alloy heating wires.

2. Equipped with a vacuum pump system to extract oxygen from the furnace before heat treatment. In order to ensure the lowest possible oxygen content, the furnace will be washed with inert gas after vacuuming. This process will be cycled several times to make the furnace tank have a pure atmosphere environment. After the oxygen content is reduced as much as possible, inert gas is introduced to a slight negative pressure, and the heat treatment process starts.

3. The maximum temperature under the atmosphere is 1100 degrees Celsius. If necessary, the furnace door can be heated. The furnace door is water-cooled. The gas is introduced into the furnace tank and preheated through the radiation layer of the furnace door. The gas diffuses from front to back. It can be manually controlled or the automatic control system can be selected.

4. The furnace material is made of high-quality alumina polycrystalline fiber vacuum adsorption, which saves 50% energy and has a uniform heating temperature field on three sides. The heating element uses high-quality resistance wire. . The furnace body adopts a double-layer furnace shell structure, and a fan is installed between the double-layer furnace shells, which can quickly increase and decrease the temperature, and the surface temperature of the furnace shell is low.

Advantages of high vacuum annealing furnace, vacuum brazing furnace and vacuum heat treatment furnace

1. Accurate atmosphere control and high purity

2. High airtight furnace tank, which can achieve high vacuum

3. Rapid heating, optional rapid cooling

4. Optional hydrogen partial pressure control

5. Tail gas combustion device system to handle combustible and toxic gases

6. Fully automatic operation or manual operation

7. Data recording for quality management

Technical Parameters:

| Product Model | KS-VF-AF200 |

| Chamber Sizes (Diameter × Depth in mm) | Φ200×400 |

| Temperature Range | 600 / 900℃ |

| Power | 15kW |

| Voltage | 380V (3-phase)

|

| Current Options | 3×32A |

| Vacuum Level | 10⁻² Torr to 10⁻⁶ Torr |

| Protective Gas | Nitrogen or Argon |

| Controller | Manual / Automatic operation

|