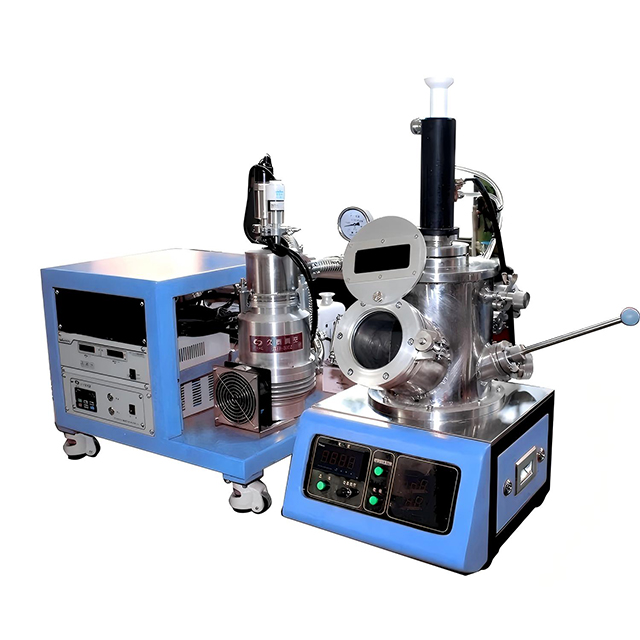

Product introduction: KS-VF-GAP300 gas atomized metal powder preparation system is the newly developed metallurgical equipment, which can be used to prepare iron-based metal powder, nickel-based metal powder, copper powder, precious metal powder and so on. Compared with similar equipment, it is not only widely used, but also has the advantages of small size, easy operation and convenient cleaning. It is an ideal equipment for laboratory preparation of material powder.

Technical Parameters:

| Product number | KS-VF-GAP300 gas atomized metal powder preparation system |

| Installation condition | This equipment is required to be used at an altitude of 1000m or less, a temperature of 25 °C ± 15 °C, and a humidity of 55% Rh ± 10% Rh. 1.Water: The equipment is equipped with a self-circulating cooling water machine (filled with purified water or deionized water) 2. Electricity: AC380V 50Hz, must have a good ground 3. Gas: the equipment chamber needs to be filled with nitrogen / argon (purity of more than 99.99%), you need to prepare your own nitrogen / argon gas cylinder (with Ø10mm double ferrule joint) and pressure reducing valve 4. Venue: Equipment size 2700×2600mm×3200mm, bearing capacity over 2200kg5. ventilation device: need |

| Main feature | The induction coil is heated. 3, small size, easy to operate.4. Low oxygen content.5, clean and easy to install.6, integrated touch screen control It can prepare a variety of powders and is widely used. small size, easy to operate. Low oxygen content. clean and easy to install.

6, integrated touch screen control |

| Technical Parameters | 1. Power supply voltage: 380V 50Hz 2. Maximum power: <20KW3. Limit Vacuum: <8E-5mbar4. Pressure rise rate: <0.67Pa/h5. Melting Vacuum Chamber Size: E500 *430mm6. Working temperature: below 1600 C7. Induction smelting power supply: 15KW 20-100KHZ8. Size of induction coil: Bah 48 *90mm9. Induction power supply cooling mode: water cooling10. Water cooling pressure: 0.2-0.3 MPa11. Melting crucible: Ba 38 *155mm12. Sphericity: about 113. Average Particle Size of Powder: D50 < 50um14. Single milling: 40-300g15. Atomization time is about 20-150 s |

| Product specification | The size of the whole machine is 2700 x 2600 mm x 3200 mm.Weight: 2.2T |