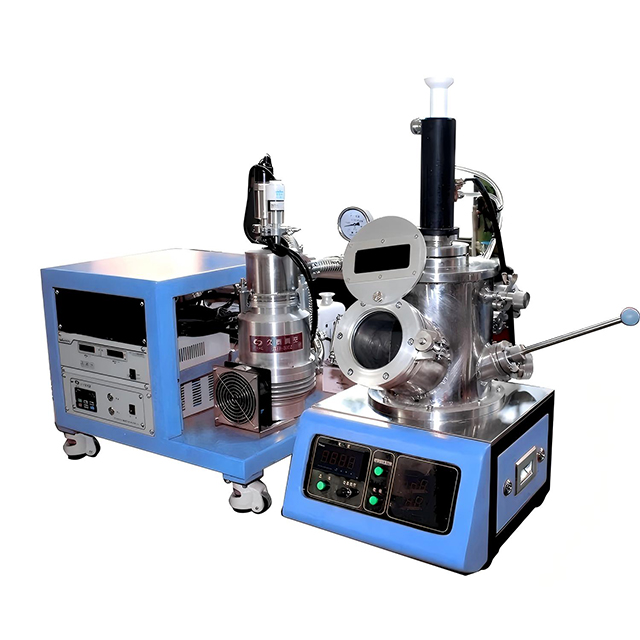

Product Description:

Continuous casting machines are mainly used for alloy melting and casting in the bonding wire industry.

In the precious metal casting industry, continuous casting machine technology is relatively mature. Compared with mold casting, it has the advantages of saving costs, improving the quality of ingots, and being easy to adopt automatic control technology. It is suitable for casting gold, K gold, silver, copper, brass and their alloys, and can pull out round bars, square bars, round tubes and other materials.

Technical Parameters:

| Model | KS-VF-CC10 |

| Heating Power | 35Kw |

| Voltage | 380V,3 phase ,50Hz |

| Melting capacity | 10Kg (Copper) or customized |

| Max melting temperature | 2000C |

| Heating method | Induction heating |

| Copper rod diameter | 6-10m |

| Pulling speed of copper rod | 100-1000mm/min (adjustable) |

| Optional function for choose | Mechanical Stirring or Ultrasonic stirrring |