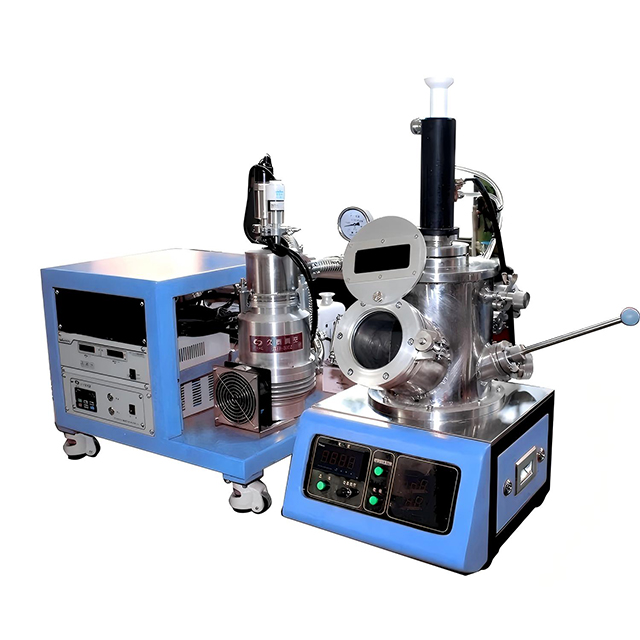

Product Description:

KS-IMCS-2000- is a streamlined high vacuum induction melting & casting furnace, can melt a variety of alloys, the maximum melting capacity can reach 1kg (according to Fe density), the maximum melting temperature can reach 2000 °C, equipped with a secondary feeding mechanism, can be used in vacuum or atmosphere protection environment for secondary feeding. A high-temperature stirring mechanism is installed to stir the melted sample at high temperature in a vacuum or atmosphere environment to make the melting more uniform. Vacuum levels up to 10-6Torr (with molecular pump system). This device is an inexpensive metal research tool.

Product Features:

1. The price is cheap, and the low cost can be used for metal melting and casting under the protective atmosphere

2. The maximum melting amount can reach 1kg (calculated according to the density of Fe)

3. With manual pouring function, the sample can be poured in a vacuum or atmosphere protection environment

4. It is equipped with a secondary feeding mechanism, which can be carried out for secondary feeding in a vacuum or atmosphere protection environment

5. A high-temperature stirring mechanism is installed, which can stir the melting sample at high temperature in a vacuum or atmosphere environment to make the melting more uniform

Technical parameters:

| Product name | 2000°C vacuum induction melting/pouring furnace |

| Product model | KS-IMCS-2000 |

| Technical parameters | Power requirements | Input voltage: 380 VAC, three-phase (or 220VAC, three-phase) 2. Maximum current: 35A3, maximum output power: 15KW

|

| Vacuum chamber | 1. The vacuum chamber is made of SS304 stainless steel 2. The size of the vacuum chamber: Φ320mm x 320 mm3. There is a quartz observation window (diameter Φ120mm) on the door of the warehouse, which is convenient for observing the sample 4. There is a shake handle, which can shake the crucible for casting the sample in an atmosphere protection environment 5. A KF25 and a KF40 interface at the back of the cavity 6, KF60 interface on the left side of the cavity for connecting the molecular pump system 7, with a crucible dumping device, It can be used to pour samples into water-cooled copper molds or graphite molds8, customers can order pouring molds in our company9, optional water-cooled copper molds10, there is a KF25 interface on the top for connecting manual secondary feeding mechanism (optional), 3 materials can be added to the melting crucible during melting |

| High temperature mixing mechanism | 1. High-temperature stirring mechanism is installed, which can stir the melting sample at high temperature in vacuum or atmosphere environment to make the melting more uniform 2. Stirring paddle material: BN3, speed: 0-200rpm (adjustable)

|

| Atmosphere protection | 1. The furnace body design can be introduced into high-purity Ar gas, the air pressure can reach 0.05Mpa2, the test range of mechanical pressure gauge installed on the equipment is -0.1MPa-0.2Mpa3, and the float flowmeter (0.2-2L/min) is installed on the equipment to adjust the inlet air flow 4. Vacuum degree: 10-2Torr (using mechanical pump), 10-6Torr (using molecular pump system) 5. Vacuum pump is not included in the standard configuration, and various vacuum pumps can be purchased in the company |

| Induction heating power supply | 1. 15KW (30-80Khz) generator with time controller and power controller 2. Induction coil: Φ90 mm x 80 mm H3, other sizes of coil can be ordered 4. Water cooler of 58L/min is required in the equipment for water cooling (not included in the standard) |

| Temperature control | 1. No temperature control system 2. The output power of the induction power supply can be adjusted to achieve the purpose of melting different metals |

| Product specifications | Size: 850mm×660mm×1700mm |