| Power Requirements | Input Voltage: 208 - 240V AC, three phases. |

| Max. Current: 35A |

| Output: 25KW |

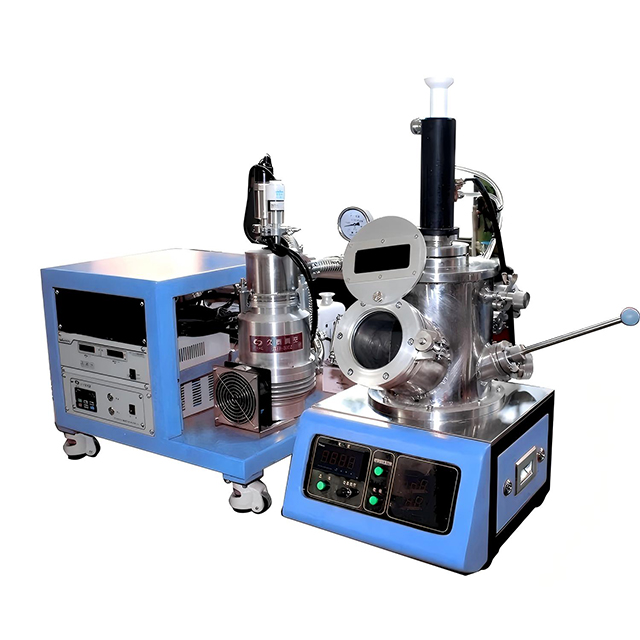

| Vacuum chamber | Vacuum chamber made of stainless steel with water cold jacket |

| Vacuum Chamber dimension: 400 mm Dia. x 400 mm Highlight |

| Vacuum level can achieve 10-6 torr ( cold status) |

| Built-in Quartz window ( 120 mm dia ) for observation. |

| Build in turbopump, which can achieve 6x10-6 torr |

| Built-in charger adding port, which allows more sample can be added during melting. |

| Built-in crucible tilting mechanism to allow cast the melt into a water cold copper or refractory mold |

| Customized casting mold is available upon request at extra cost. |

| Standard casting mold size: D50x90mm ( customized size available upon request ) |

| Atmosphere | The furnace can fill inert gas up to 0.5 Bar. |

| Induction Heating | 15KW (30-80Khz) Dual Station Bench Top Induction Heater with Timer Control & Temp Controller Port |

| 58 L/minute cooling water is required, but not included |

| Induction Coil: 60 mm ID x 80 mm Height, including one. |

| The customized induction coil is available upon request |

| Temperature Control | Programmable Temperature control with overheated protection via standard thermal couple or optical sensor upto 2000°C (please choose working temperature range before order) |

| K type T/C -- 1200ºC Max. |

| B type T/C -- 1700ºCMax |

| C type T/C - - 1800ºC Max. |

| IR optical temperature sensor: 2000ºC Max. ( optional ) |

| Warranty | One-year limited warranty with lifetime support |

| Dimensions | 1250 x1150 x 1500 ( L xWxH ), mm |

| Net Weight | ~500kg |