Product Description:

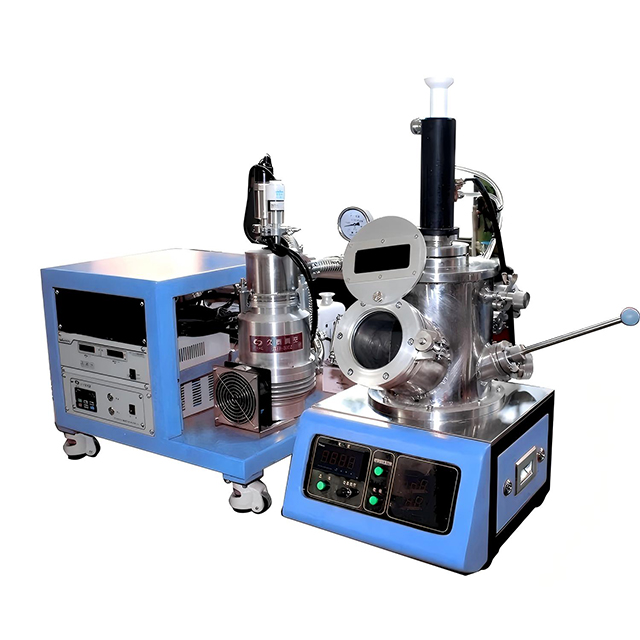

The vacuum air atomization powder making device includes

Vacuum melting furnace, supersonic nozzle system, temperature control system, atomization tower system, cyclone separation system, vacuum system and control system can realize functions from 500g to 100kg. Equipped with induction heating and plasma heating;

For the evacuation system different types of pump sets and all brands on the market can be used;

According to the process requirements, 10Pa ~10-4Pa can be obtained. And can be filled with high-purity inert gas (such as nitrogen, argon and helium, etc.)

Applicable material range of vacuum air atomization powder making device

MIM powders for solder and brazing metals wear resistant coatings components

Sputtering Targets to Produce Electronics

3D printing and thermal spraying

Nickel-based superalloys for the aerospace industry and electrical engineering

Advantages of vacuum smelting inert gas atomization powder making device technology:

Melt temperature up to 2600°C Melting speed adjustable

Adjustable air speed

By adjusting the air volume of the cyclone separation fan;

Realize the separation of coarse and fine powder

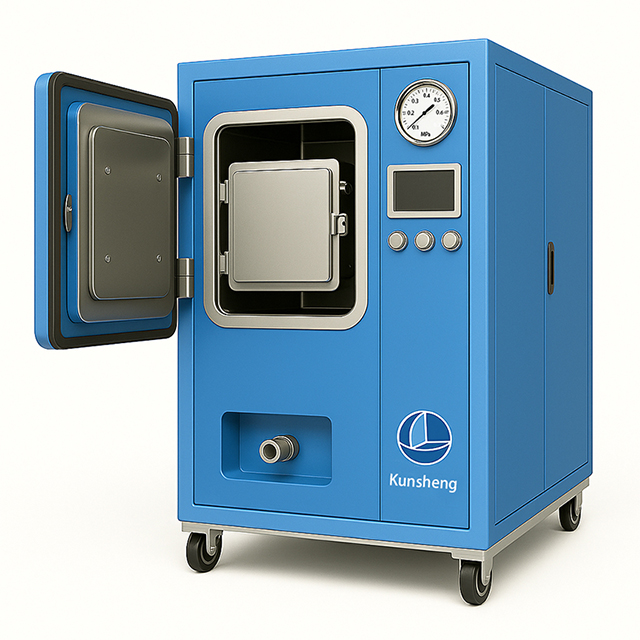

Technical Parameters:

| Modle | KS-VF-VAM1 |

| Total power | 35Kw |

| Voltage | 380V,3 phase,50Hz |

| Max Melting temperature | 1600C |

| Max atmosphere melting temperature | 2600C |

| Max pressure for atomizer | 4-15 Mpa |

| Powder oxygen content | ≤100 PPM |

| Limit vacuum | ≤8×10ˉᶟ Pa |

| Safety valve | 0.01-0.1Mpa adjustable |

| Spray tower vacuum chamber leak rate | ≤0.67Pa/ hour |

| The height of Equipment | Less than 3.5m |