Product Description:

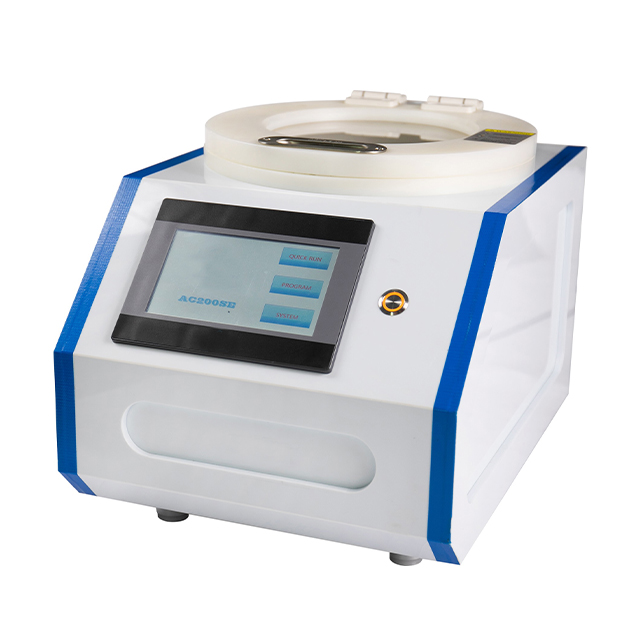

KS-ESP-USC300 ultrasonic atomization

spin coating machine is a liquid film preparation equipment integrating

ultrasonic atomization, liquid injection and spin coating. The equipment

adopts a box structure, KS-ESP-USC300 ultrasonic atomization rotary film

coating machine, the glue sprayer uses a microprocessor to control the

volumetric pump to deliver the solution accurately; the atomizer is fixed on a

support arm that can swing within a certain range, so as to ensure The

uniformity of the coating, through the deposition of the mist particles sprayed

by the ultrasonic atomizer on the substrate, a thinner micro-nano coating can

be prepared; KS-ESP-USC300 ultrasonic atomization rotary coating machine, the

glue sprayer can The diameter of the substrate can be as long as 12"

(300mm), and the film can be heated and dried quickly after coating to meet the

needs of the experiment. This equipment is widely used in education and

scientific research units, as well as in the development of thin films including

solar cells.

Product Features:

1. The machine integrates ultrasonic

atomization, liquid injection, spin coating and heating.

2. It

adopts infrared heating method, and the heating speed is fast.

3. This

equipment is equipped with a vacuum pump as standard, and the vacuum pump is

used to absorb and fix the sample. The compressor enhances the directionality

of the spray and reduces the splash of the spray. The air compressor is not

standard.

4. The

liquid injection system can be equipped with a single-channel or multi-channel

liquid injection system.

5. The

equipment is equipped with an exhaust system, which can clear the tank Steam

and odor of the material liquid in the body.

6. A gas

filter device can be added to filter the toxic and harmful gases discharged to

reduce environmental pollution.

7. The equipment is equipped with an

infrared alignment mechanism, which can use infrared rays to determine the

starting position of spraying

8.The LED lighting system is used in

the box, which has a longer service life and brighter light.

9. There is

a movable thermocouple in the box, which can accurately measure the temperature

of each point in the box.

10. The

ultrasonic atomization nozzle station can be increased , up to 4 stations.

Technical Parameters:

| Model | KS-ESP-USC300 |

| Power supply | 220V 50Hz, total power <1800W |

| Arm swing angle | 0-60°; swing arm speed 1-20°/s adjustable |

| Coating time | 1-999s adjustable |

| Spindle speed | 30-3000rpm (30rpm integers are increments) |

| Infrared heating | RT—80°C, heating power 1000W |

| Sample loading plate diameter | φ203mm, the maximum diameter of the film-coating sample is 12 inches. |

| Ultrasonic nozzle frequency | 40KHz; amplitude gear 1, 2, 3 gears can be switched. (The total power of the ultrasonic controller is 200W, and the control current is automatically adjusted.) |

| The diameter of the exhaust outlet | φ100mm. |

| Total weight of equipment | 100kg |

| Liquid Particle size | 10um-20um Particle size ≤50um |

| Liquid Flow size | ≤0.35ml/s |

| Liquid Solid content | ≤ 10% |

| Liquid Viscosity size | ≤ 35cPs |

| Product Dimensions | 600×600×800mm |