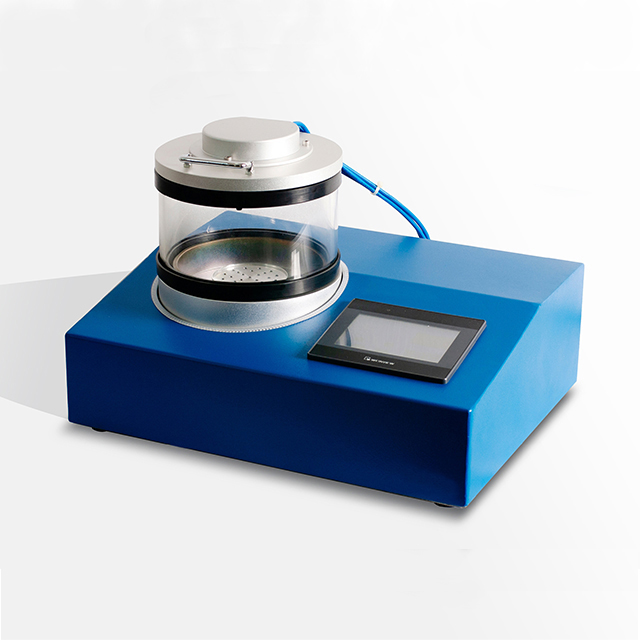

Product description:

This system is a spherical pulsed laser deposition system (PLD) process research and development equipment. Pulsed laser deposition (PLD) is a method of focusing the laser on a smaller area on the target material, using the high energy density of the laser to evaporate or even ionize part of the target material, so that it can break away from the target material and move toward the substrate, and then deposit on the substrate to form a thin film. Among the many thin film preparation methods, pulsed laser deposition technology is widely used. It can be used to prepare thin films of various materials such as metals, semiconductors, oxides, nitrides, carbides, borides, silicides, sulfides and fluorides, and even to prepare some difficult-to-synthesize material films, such as diamond and cubic nitride films.

Technical Parameters:

| Product name | spherical pulsed laser deposition system (PLD) |

| Product model | KS-PD-PLD01 |

| Vacuum Chamber Structure | Spherical chamber with manual front-opening door |

| Vacuum Chamber Material | 304 stainless steel, argon arc welded, surface treated by glass bead blasting and electrochemical polishing/passivation |

| Vacuum Chamber Size | Φ300mm, equipped with a visual observation window |

| Ultimate Vacuum | ≤6.67×10⁻⁵ Pa (with 600 L/S turbomolecular pump and 8 L/S fore pump after baking and degassing) |

| Leak Detection Rate | ≤5.0×10⁻⁷ Pa·L/S |

| Pumping Time | From atmosphere to 8.0×10⁻⁴ Pa in approximately 40 minutes |

| Vacuum Retention | ≤20 Pa after 12 hours of shutdown |

| Sample Stage Size & Speed | Sample size Φ40mm, rotation speed 1–20 RPM, distance between target and substrate 40–90mm |

| Sample Heating | Maximum temperature 800℃, temperature control accuracy ±1℃, controlled via temperature controller |

| Rotary Target Structure | Four-position rotary target, each target Φ40mm, shield exposes only one target, supports both revolution and rotation |

| Additional Features | Chamber equipped with baking, illumination, and water pressure alarm system |

| Gas Inlet System | One MFC for gas flow control, range 0–100 sccm |