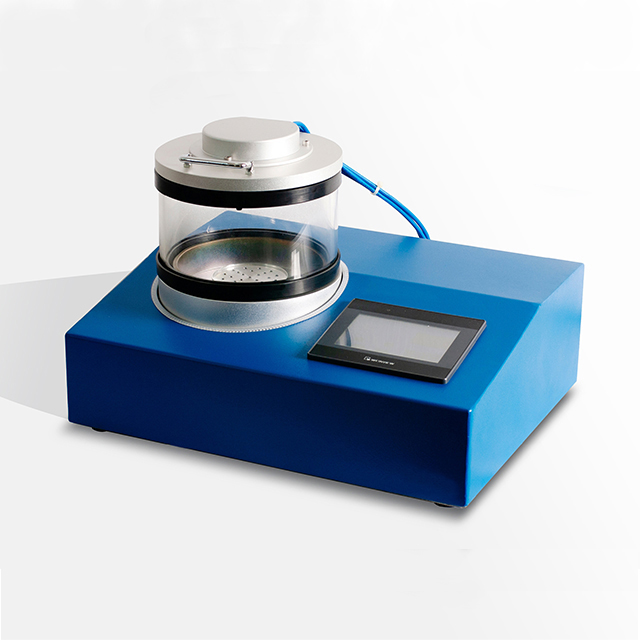

Product Description:

KS-DBC-3D small cast automatic

drying coating machine is a bottom heating type small automatic casting film

scraping machine designed and developed by our company. It is mainly used for

coating liquid or colloidal films in laboratories. The equipment adopts a

stepless variable speed motor to precisely control the coating film speed, so

as to achieve the purpose of advancing the scraper at an even speed for

coating. The scraper is made of all stainless steel and has a constant weight,

which can improve the consistency and uniformity of the coating film. The

equipment adopts bottom vacuum to absorb samples, and has bottom heating

function. The heating temperature can reach up to 120°C. During the film

coating process, the film drying function can be realized at the same time, so

that the film can be dried quickly. KS-DBC-3D small casting automatic

drying film coating machine is equipped with a scraper limiter, which can

adjust the length of the coated film arbitrarily, and the scraper will

automatically reset when it reaches the limit. The upper cover has the

functions of dustproof and heat preservation, and at the same time makes the

equipment more beautiful. The company's small casting automatic coating

film dryer is carefully designed for the convenience of operators to coat

high-quality wet films on different substrates, which greatly improves the

repeatability of coating films.

Product Features:

·The equipment adopts stepless

variable speed motor to precisely control the coating speed.

·A cross bar

is used to push the wet film preparation device, and there is no special

requirement for the external dimension of the wet film preparation device.

·The waste collection box placed on the left edge of the vacuum suction plate

can collect excess paint to ensure the cleanliness of the equipment itself and

the surrounding area.

·Intelligent

vacuum heating suction plate and digital display temperature control drying

system can adapt to the development of science and technology of film formation

under high temperature conditions.

·The

machine adopts the bottom heating method, and bakes the glue in the process of

gluing.

Technical Parameters:

| Product Model | KS-DBC-3D |

| Power supply | AC 220V, 50HZ |

| Total power | 1100W |

| Heating plate area | 360mm×200mm (length×width) |

| Vacuumable size | 300mm×150mm (length×width) |

| Coating speed | 10mm/ s-100mm/s (infinitely variable speed) |

| Coating stroke | 10-250mm (length adjustable) |

| Maximum heating temperature of the heater | 120°C (200°C) |

| Temperature control accuracy | ±1°C |

| Control Membrane | 150mm micron-level adjustable (other sizes can be selected), adjustment range 0.01mm-5mm |

| Membrane precision | ±10μm |

| Overall dimensions of the whole machine | closed state 620mm×400mm×320mm (length×width×height);open state 860mm×400mm×790mm (length×width×height) |

| Weight | 60Kg |