Product Description:

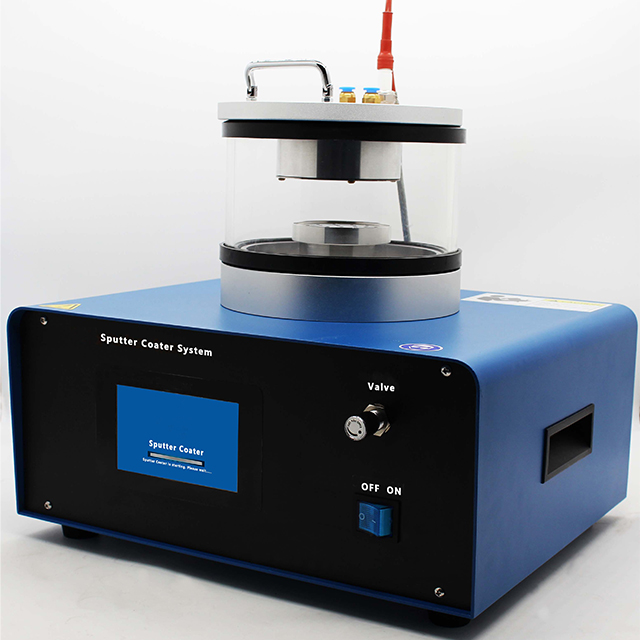

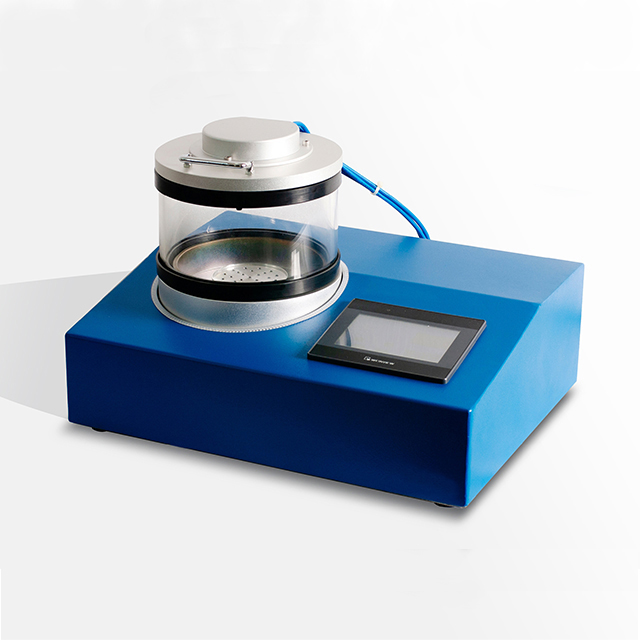

Parallel plate capacitor PECVD is a technology that uses plasma to activate reactive gases, promote chemical reactions on the substrate surface or near the surface space, and generate solid films. The basic principle of plasma chemical vapor deposition technology is that under the action of high frequency or DC electric field, the source gas is ionized to form plasma, and low-temperature plasma is used as an energy source. An appropriate amount of reactive gas is introduced, and plasma discharge is used to activate the reactive gas and realize chemical vapor deposition. This system is a single-chamber plasma enhanced chemical vapor deposition (PECVD) process research and development equipment, which is used to grow nanowires or use CVD methods to make various thin films. It is a new exploration tool.

Technical Parameters:

| Product name | Parallel plate capacitor PECVD |

| Product model | KS-PECVD-300 |

| System Structure | Single-chamber cylindrical structure with manual front-opening door |

| Vacuum Chamber Material | Made entirely of high-quality 304 stainless steel, argon arc welded, with glass bead blasting and electrochemical polishing and passivation |

| Observation Window | Equipped with a visible observation window and baffle |

| Vacuum Chamber Size | Φ300mm × 300mm |

| Ultimate Vacuum | 8.0×10⁻⁵ Pa (after baking and degassing, using a 600 L/S turbomolecular pump and 4 L/S fore pump) |

| Leak Detection Rate | ≤ 5.0×10⁻⁷ Pa·L/S |

| Pumping Time | From atmosphere to 8.0×10⁻⁴ Pa in approximately 40 minutes |

| Vacuum Retention after Shutdown | ≤ 20 Pa after 12 hours of shutdown |

| Gas Inlet Mode | Capacitively coupled inlet, sample at bottom, showerhead at top |

| Sample Heating Capacity | Maximum temperature 500°C, temperature control accuracy ±1°C, controlled by temperature controller |

| Showerhead Size | Φ90mm |

| Electrode Distance | Distance between showerhead and sample adjustable from 15 to 50mm with inline continuous adjustment and scale display |

| Working Pressure Range | 13.3 – 133 Pa (adjustable based on process requirements) |

| RF Power Supply | Frequency 13.56 MHz, maximum power 300W, fully automatic matching |