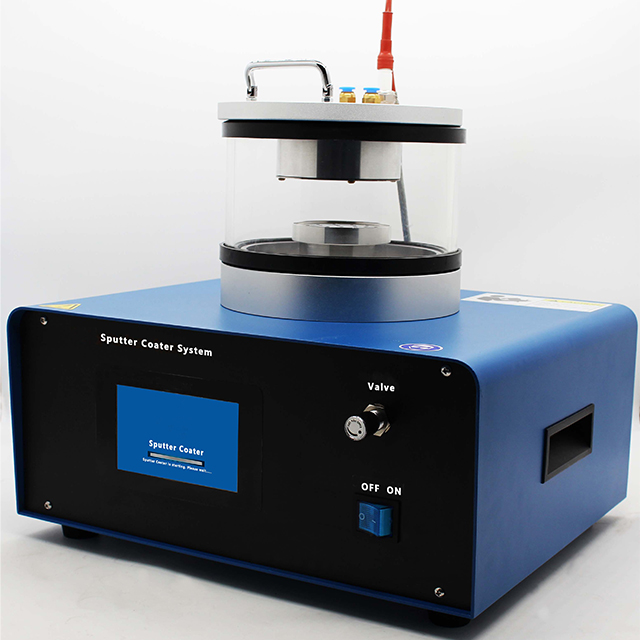

| Model | KS-MIB-560 |

| Vacuum chamber size | Vertical cylindrical, size Ф550×450mm |

| Vacuum system feature | Compound molecular pump, mechanical pump, gate valve |

| Ultimate pressure | ≤6.67x10-5 Pa (after baking and degassing) |

| Time required to reacquire vacuum | 6.6x10-4 Pa in 40 mins (pumping after short exposure to air and filled with helium) |

| Water cooling substrate heating revolution table | Substrate size | 6 stations design, one station for heating furnace installation, rest of the station are water cooling substrate table |

| Sample size | Load 6 piece of Ф30mm substrate |

| Mode of motion | Rotating 0-360°continuously |

| Heating | Max heating temperature 600°C±1°C |

| Substrate negative bias | -200V |

| Magnetron target unit | Permanent magnetron target × 4; target size Φ60mm (one of those can be used for sputtering ferromagnetic material); all targets are RF sputtering and DC sputtering compatible; distance between target and sample: 40-80mm, adjustable |

| 4 stations revolving target unit | Target size: 70×70mm |

| Primary sputtering ion gun | Extraction grid diameter: Φ30mm; ion beam power: 0.4~2.0Kev adjustable continuously; ion current intensity: 1~5mA/cm2 |

| Auxiliary deposition ion gun | Extraction grid diameter: Φ30mm; ion beam power: 0.4~1.5Kev adjustable continuously; ion current intensity: 1~3mA/cm2 |

| Gas circuit | 3-circuit mass flow controller |

| Computer control system | To control target baffle, 4 station rotating target position change, sample revolution, sample baffle, sample temperature control |

| Space occupied | Main unit | 1300×850mm2 |

| Electric cabinet | 700×700mm2(Two) |