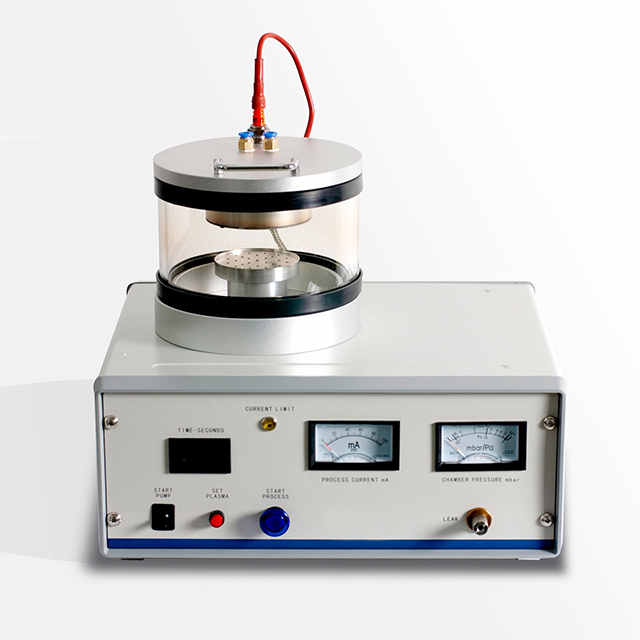

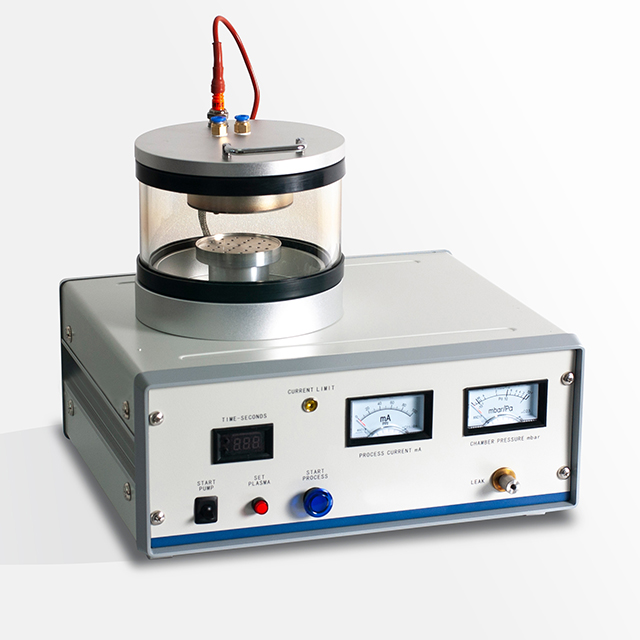

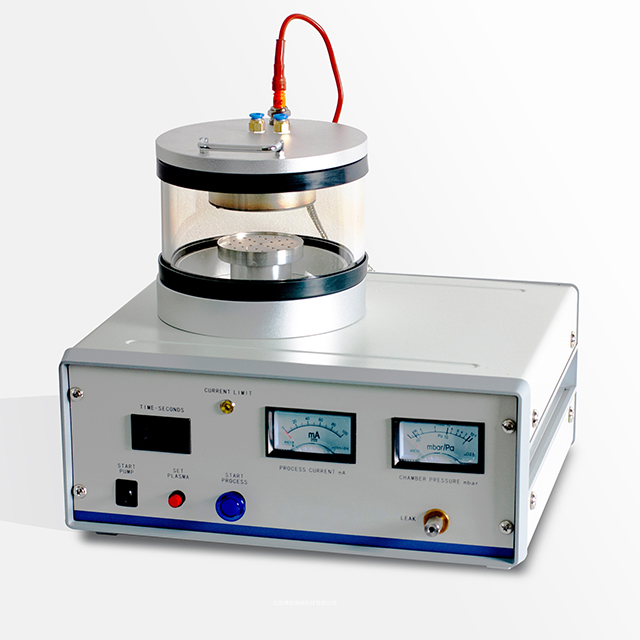

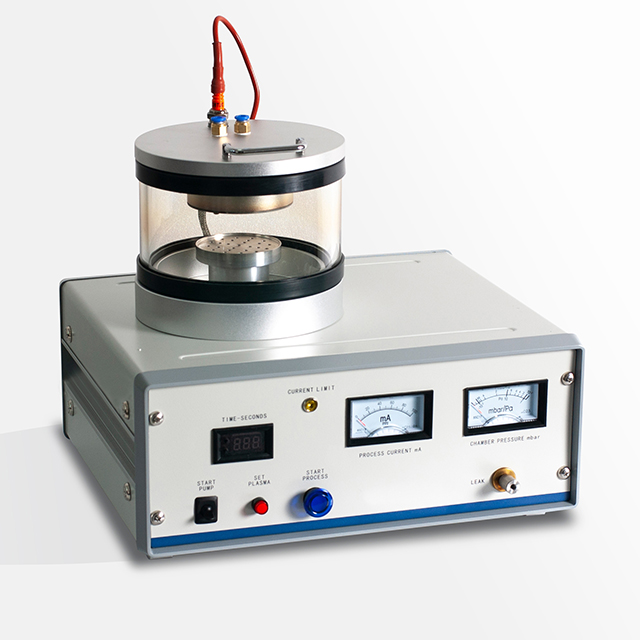

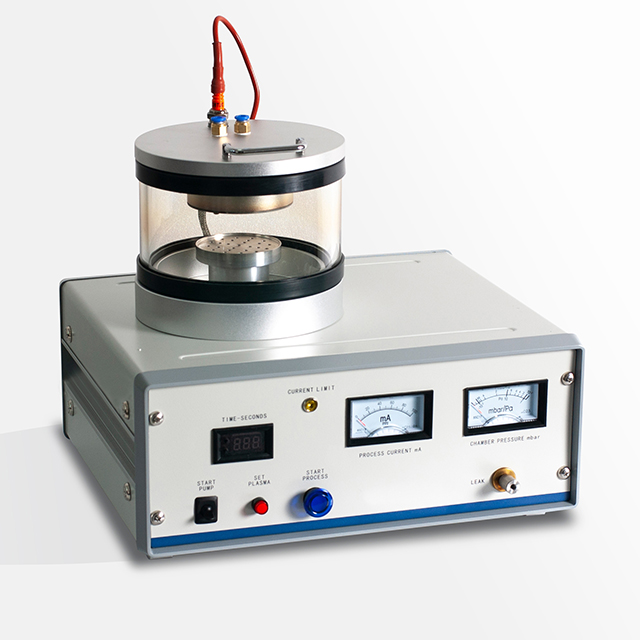

Magnetron Ion Sputtering Coater (KS-SD-900M Model) is ideal and designed for lab SEM sample preparation. It is widely used to coat non-conductive or heat-sensitive SEM samples with Au for better imaging. It is also excellent for surface treatment and avoids damage to the substrate sample.

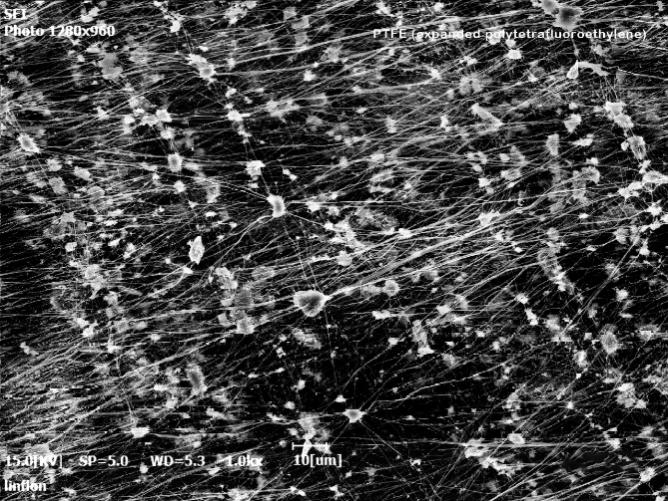

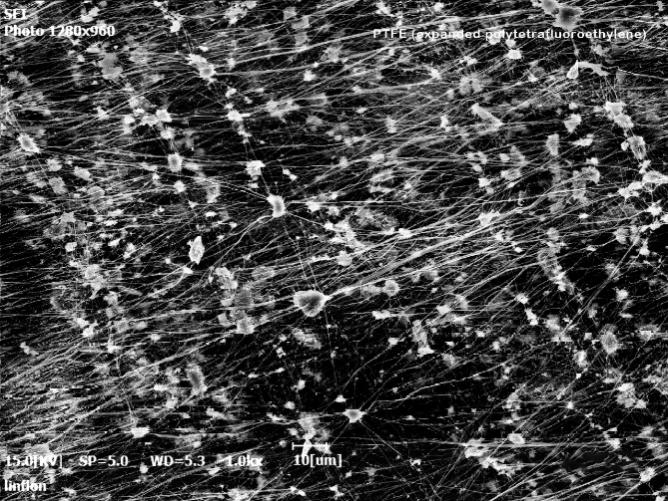

Coating Result Sample Picture under SEM (by KS-SD-900M Model) EPTFE (Extended Poly Tetra Fluoro Ethylene)

Low vacuum, can be achieved quickly when using proper vacuum pump within 5 minutes. It generates much less heat and avoids plasma damage to the substrate sample. It is user friendly and easy to operate.

Vacuum pump is included. Chiller is optional.

Technical Parameters:

| Model | KS-SD-900M magnetron sputtering coater/coating machine |

| Vacuum pump set | (Oil required) rotary vacuum pump |

| Rotary pumping speed | 50 Hz : 8 m³/h (2.2 L/s)/ 60 Hz : 9.6m³/h (2.6 L/s) |

| Vacuum limit | 2 Pa |

| Max sputtering current | 100mA |

| Working pressure | 20Pa - 8 Pa |

| Vacuuming time | <5 Min(2 Pa) |

| Vacuum measure | Measuring range from atmosphere to 2*10-2mbar |

| Chamber size | Φ150*120mm (height) scratch resistant quartz glass |

| Magnetron target source | Target size φ50*0.1mm(Au)/target source: Au,Ag,Pt |

| Operation method | Instruction Manual |

| Weight/size | 45kg/360mm length x 300mm wide x 380mm high |

| Power supply | AC 110V 60Hz or AC 220V 50Hz |

| Power consumption | <1500W |

| Cooling method | Water cooling(optional) |

| Warranty | One year limited warranty with lifetime product support |