Mar. 01, 2021

The magnetic character of a material is determined by the spins (magnetic moments) of its electrons. Whereas electric charge is a scalar quantity, possessing only magnitude, spin is a vector — it has both a magnitude and a direction. This feature affects the interactions of spins and leads to the formation of microscopic spin textures. Such textures are responsible for the behaviour of magnetic materials and are decisive in technologies ranging from nanoscale applications in magnetic hard disk drives to large-scale permanent magnets in high-power electronics. Being able to visualize complex spin textures in 3D with high spatial resolution is therefore of paramount scientific and technological interest. On page 328, Donnelly et al.1 report an X-ray imaging technique that achieves this feat. The technique could open the door to a better understanding of magnetic materials and the creation of tailor-made magnetic devices.

Exploring magnetic materials in one or two dimensions has led to many remarkable discoveries. Examples include the giant magnetoresistance effect2,3 that resulted in the 2007 Nobel Prize in Physics and triggered a technological revolution in magnetic storage and sensor technologies, and the unexpected discovery earlier this year of intrinsic magnetism in atomically thin 2D van der Waals crystals4. But because space is at a premium in magnetic devices, tremendous efforts are underway to increase storage capacity by taking advantage of the third dimension5,6. The vector character of spin means that spin textures can be much more complex than 3D charge configurations, potentially giving rise to materials that have unique properties, and devices that have unprecedented functions. However, substantial advances in synthesis, modelling and metrology are required to succeed in this area.

Polarized X-rays have several features that are essential for characterizing the static and dynamic properties of magnetic materials. The polarization provides sensitivity to magnetic properties because of an effect called spin–orbit coupling, in addition to angular-momentum conservation in the interaction between the X-rays and the material. The wavelength associated with X-rays sets an ultimate limit on the spatial resolution of X-ray imaging in the sub-nanometre range. X-rays can travel thousands of nanometres through bulk material before being absorbed. Finally, temporal resolution down to the femtosecond range (1 fs is 10−15 seconds) is possible using X-ray flashes generated from state-of-the-art X-ray sources.

Similarly to optical lasers, one of the most intriguing properties of X-rays is coherence — when two overlapping waves have the same frequency and a constant phase difference. The latest developments in X-ray sources have aimed to increase coherence to take advantage of the generally hidden phase information contained in the waves and to bring the numerous achievements of optical lasers into the nanoscale world7.

In the past decade8,9,10, X-ray optics have been able to generate 2D images with a spatial resolution of about 10 nm. A technique called tomography can be used to computationally reconstruct 3D objects from sets of these images, which are usually captured from a range of projection angles. This technique is now routinely used in biology11 and materials science. However, because the spatial resolution is still far from the sub-nanometre wavelength limit of X-rays, researchers have started to develop alternative approaches that are based on X-ray diffraction, rather than reflection or absorption.

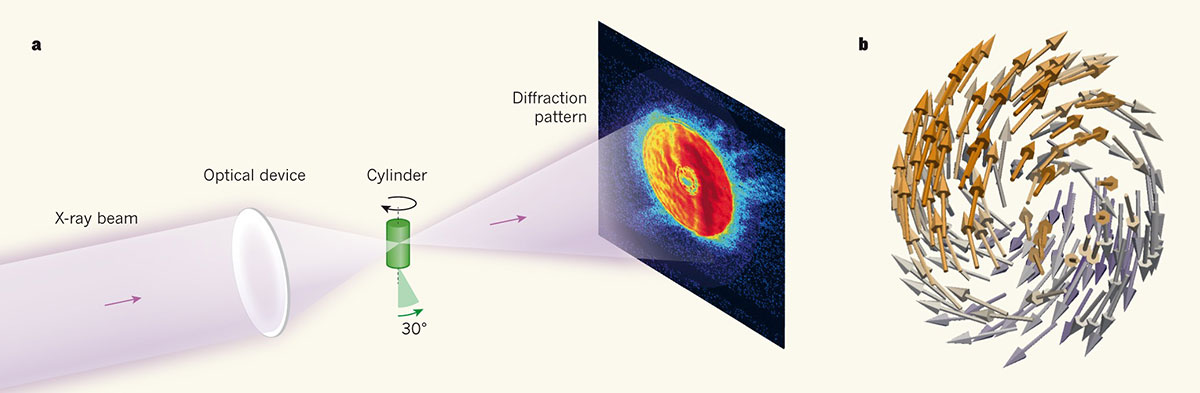

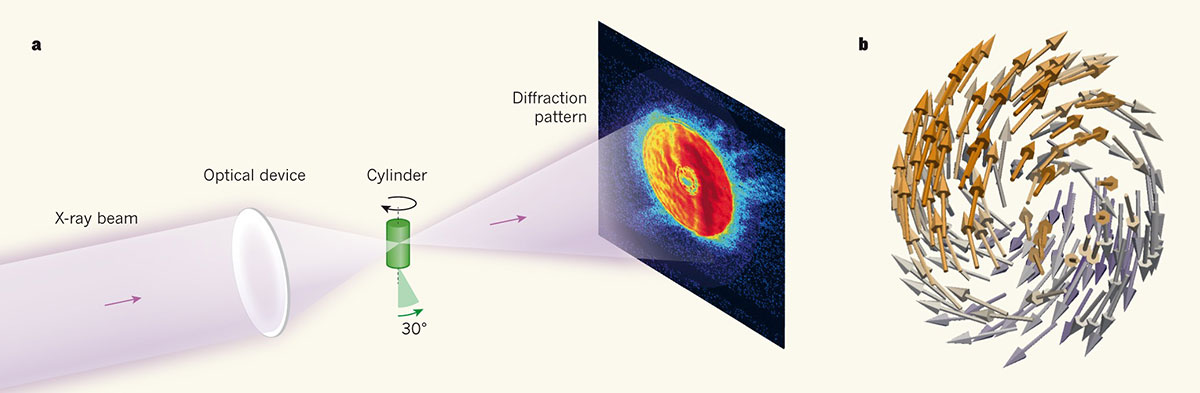

Donnelly and colleagues' imaging technique uses such an approach, called X-ray ptychography (Fig. 1a). The authors demonstrated their technique on a gadolinium cobalt magnetic cylinder that has a 5-μm diameter. They directed a beam of polarized short-wavelength (hard) X-rays at a particular spot on the cylinder and used high-speed detectors to observe the diffraction pattern produced. By scanning the beam across the cylinder and gradually rotating the cylinder, the authors collected a series of such diffraction patterns. They then tilted the cylinder by 30° and repeated the observations — this allowed them to access all three dimensions of magnetization. Finally, the authors applied sophisticated algorithms to reconstruct images of the cylinder's magnetization, enabling them to identify complex spin textures with a spatial resolution of about 100 nm (Fig. 1b).

Figure 1: Magnetization observed using X-rays.

figure1

Donnelly et al.1 report a technique for resolving 3D configurations of electron spins (magnetic moments) in materials. a, The authors demonstrate their technique on a magnetic gadolinium cobalt cylinder. They direct a beam of polarized X-rays at a particular spot on the cylinder, using an optical device that acts like a lens. The X-rays are diffracted from the cylinder, producing a diffraction pattern — the colours indicate the intensity of X-rays, from black (low) to dark red (high). By scanning the beam across the cylinder and gradually rotating the cylinder (black arrow), the authors collect a series of diffraction patterns. They then tilt the cylinder 30° (green arrow) and repeat the observations, allowing all three dimensions of magnetization to be accessed. b, Donnelly and colleagues apply sophisticated algorithms to the diffraction patterns to reconstruct images of the cylinder's magnetization. An example image is shown in which each arrow represents an electron's spin and the colours indicate the direction of magnetization from downwards (blue) to upwards (brown). Diffraction pattern in a, and b, adapted from Fig. 1a and Extended Data Fig. 3b in ref. 1, respectively.

Full size image

Although this resolution is larger than has been achieved using conventional X-ray optics, the authors' technique promises to push the spatial resolution of X-ray imaging to its fundamental limit. This would bypass the technological challenges associated with improving the efficiency and resolution of conventional X-ray optics. Two achievements support this promise. First, a spatial resolution of a few nanometres has been demonstrated in ptychography using long-wavelength (soft) X-rays12. Second, hard X-ray ptychographic tomography was used earlier this year13 to achieve non-destructive 3D imaging of integrated circuits — albeit without magnetic sensitivity — with a spatial resolution of 14.6 nm. This makes the tool highly attractive for real-world applications, for example in the industrial quality control of nanoscale technological devices.

Donnelly and colleagues' work is a landmark in the development of advanced metrology for magnetic materials, but it has not yet reached its full potential. The main challenge for magnetic X-ray microscopy in the future will be to keep up with the length scales in relevant magnetic devices — in existing devices, such scales are already smaller than the resolution offered by state-of-the-art X-ray ptychography. For comparison, tomography using electron microscopes has imaged 3D structures with single-atom precision14.

An advantage of magnetic X-ray microscopy over other techniques will be its ability to characterize buried interfaces15 — particular spins in the regions between materials that have a large and distinct spin–orbit coupling. These spins can generate robust (topologically protected) spin textures that offer improvements in storage capacity, energy efficiency and data-transfer speed with respect to current technologies. Being able to see individual spins flowing in real time through such interfaces sounds like science fiction, but with the prospects of X-ray technologies on the horizon, it might become reality in the near future.Footnote1