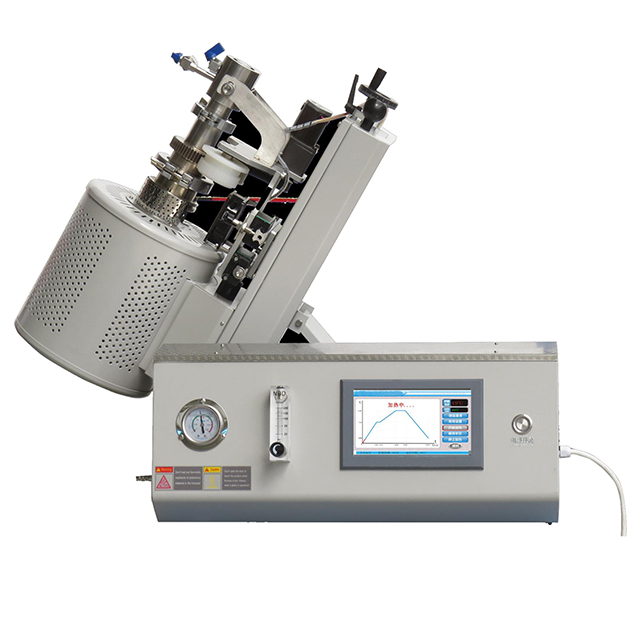

Product Description:

The mini stirred sintering tube furnace is suitable for experimental equipment for heat treatment of various materials. The main industries include rare earth preparation, electronic lighting, crystal annealing, bioceramics, electronic ceramics, special alloys, magnetic materials, precision casting, etc. It is mainly used in vacuum sintering, atmosphere protection sintering, vacuum coating, CVD experiment, material composition measurement and other occasions.

Product Features:

1. By rotating at a constant speed, the material can be heated and contacted with the gas more fully and evenly ;

2. High-purity Al2O3 fiber refractory insulation material, saving energy and reducing consumption;

3. High-purity alumina coating can prolong the service life of heating elements;

4. There are 4 angles (30 degrees, 45 degrees, 60 degrees, 90 degrees) adjustable, easy to replace the furnace tube

Technical Parameters:

| Product model | KS-RT1200-50 |

| Power supply | AC220V, single phase or as customized |

| Max temperature | 1200C |

| Working temperature | ≤1100C |

| Heating Rate | ≤10C/min |

| Temperature zone size | Ø80*100mm |

| Furnace tube size | Ø50×220mm (sealed at one end) |

| Heating element | Mo with Fe-Cr-Al alloy |