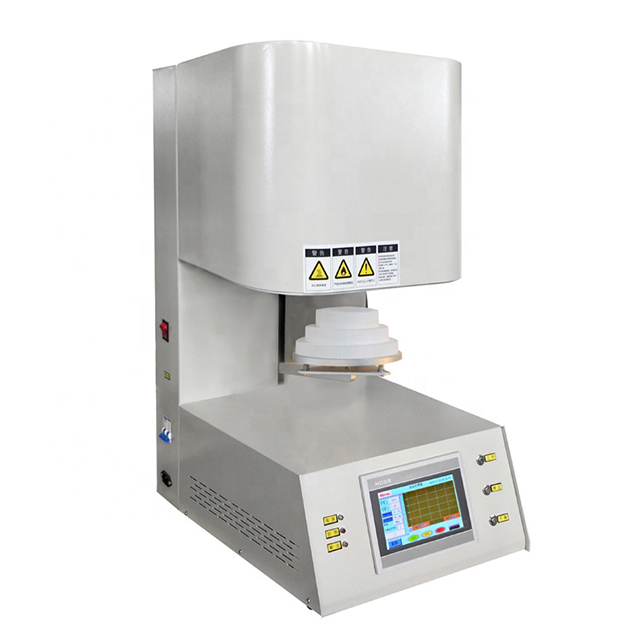

| Model | KS-MF1100-1L |

| Max.temperature | 1200C |

| Working temperature | 0-1100C |

| Furnace Chamber size(DWH)mm | 100*100*100 or as your requirement |

| Heat element | Resistance wire |

| voltage and frequency | 220v 50Hz/60Hz |

| Heating rate | 0-20C/min |

| Temperature accuracy | ±1°C |

| Thermocouple | K type |

| Temperature control | Adopt international advanced temperature controller, with 30-50 programmable PID self-tuning, automatic temperature rise, automatic temperature drop, no duty. |

| Appearance design | The electric furnace adopts humanized design, beautiful and easy to operate, and the outer layer of paint is sprayed with high temperature baking technology. High temperature resistance, oxidation resistance, acid and alkali resistance. Color selection is aging resistant tone, will not cause the appearance color fade due to a long time of use. |

| Furnace shell structure | Electric furnace shell adopts double layer forced air cooling structure, so that the electric furnace works at the highest temperature and the external temperature of the shell is close to room temperature, so as to avoid accidental injury. |

| Temperature control security | The electric furnace adopts integrated circuit, module control, double circuit protection (partial temperature protection, ultra-high temperature protection, coupling protection, overcurrent protection, overpressure protection and other protection functions) to make the electric furnace work stable and reliable, safe. |

| Furnace Chamber material | Adopt the most advanced light alumina ceramic fiber in the world, with excellent thermal insulation effect, light weight, high temperature resistance, cold and heat resistance, no crack, no crystallization, no slag, do not worry about pollution of the fired products. The energy saving effect is 60-80% of the old electric furnace. |

| Furnace chamber design | Furnace adopts the stepped assembly structure, integrating the mechanical law, effectively ensure the furnace in the heating process of uniform force, ensure that the heat is not easy to disperse, prolong the service life of the furnace. |

| Sandard accessories | Crucible tongs 1pc, Thermal gloves 1 pair,User manual 1 pc,other small tools for assembly furnace |

| Other temperature options | 1200C,1400C,1700C,1800C |

| Furnace chamber standard size | 100*100*100mm,200*150*150mm,300*200*200mm,400*300*300mm or other OEM size |

| Waranty | One year |