Description of product :

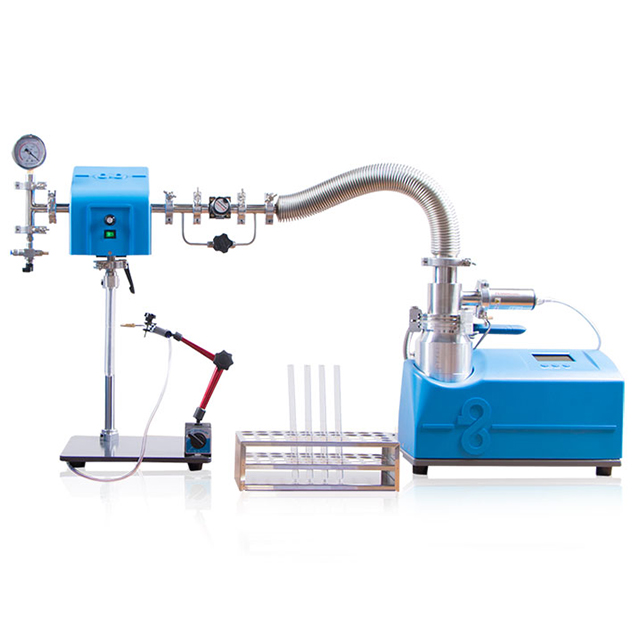

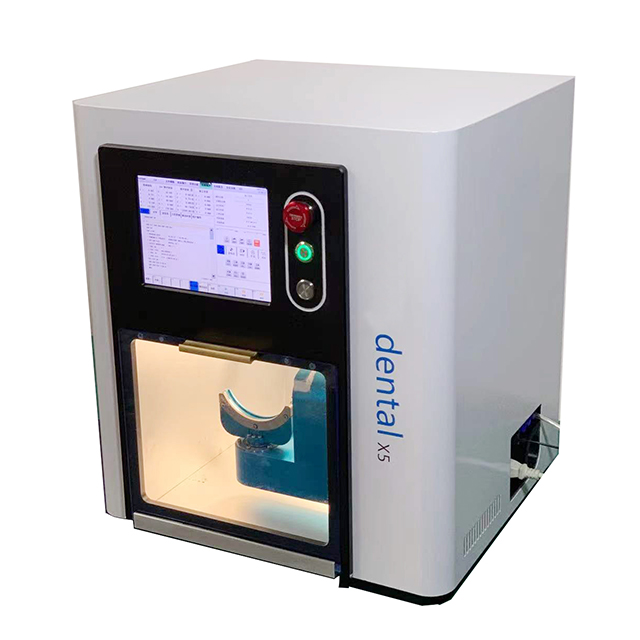

KS-MFT-1200X-2Z is a dual-zone split tube furnace with the revolving sample feeding system that can drive the crucible into processing tube at desired temperature. The two-zone split tube furnace can achieve fast heating up to 1200°C and create a different thermal gradient by setting different temperature for each zone. The revolving feed system can push and draw a crucible with evaporation material through the vacuum or atmosphere controlled quartz tube and sequentially process up to four crucibles as program, which is a perfect to conduct HPCVD experiments, especially for preparing multi-layer 2D crystal materials. Its built-in PLC touchscreen allows users to manage the feeding method and monitor the temperature of each sample. Two 30-segment programmable PID temperature controllers provide excellent control without temperature overshooting.

Technical Parameters:

| Model | KS-MFT-1200X-2Z |

| Furnace Structure | Two independent temperature controllers to control each zone's temperature.Double layer steel casing with air cooling keeps furnace surface temperature lower than 60°C. High purity fibrous alumina insulation for maximum energy saving.The special refractory coating on liner and heating element help increase furnace service life.Split cover with Interlock protection, cut the power if door open during furnace heating process. |

| Power Requirement | Single Phase 208~240VAC, 3KW (20Amp circuit breaker is required) |

| Heating Zone Length | Two zones: each zone length is 8" (200 mm)Total 16" (400 mm) heating zone |

| Constant Temp. Zone | 150mm (+/-1°C) for each heating zoneA longer constant temperature zone ( about 250mm ) can be created by setting both zones at the same temperature |

| Temperature Range | 100~1100°C (Continuous); |

| Max. Heating Rate | ≤ 20°C /min |

| Revolving Feeding System | One thermocouple connects to the crucible from the left flange .The stepper motor drives the crucible to travel through the tube together with the thermocouple for real-time temperature monitoring.Four crucibles can be simultaneously placed into the revolving feed system and sequentially delivered to the quartz tube under vacuum or inert gas |

| Crucible Movement Control | The crucible moving speed and distance are controlled by a stepper motor.Crucible traveling distance: 1mm ~ 200mm |

| Temperature Controllers | 2 digital controllers with 30 programmable segments for precise control of heating rate, cooling rate and dwell time.Built in PID Auto-Tune function with overheating & broken thermocouple protection.Over temperature protection and alarm allows for operation without attendant(s).+/- 1ºC temperature accuracy.Two K-type thermocouples (one for each zone).RS485 Communications Port. |

| Heating Element | Fe-Cr-Al Alloy doped by Mo |

| Tube Accessories | fused quartz tube (60mm O.D. x 54mm I.D. x 1000mm L) is includedTwo fibrous ceramic tube blocks are included for blocking heat radiation from inside tube. (Ceramic blocks must be fully inserted into the furnace chamber before heating) |

Digital Vacuum Gauge

| Corrosion-proof Capacitance Diaphragm Gauge with ceramic coated sensor head specially designed for vacuum measurements with the presence of corrosive gases.Provides a wide range (3.8E-5 ~ 1125 torr) of measurement. |

Vacuum Pump

| Double Stage Rotary Vane Vacuum Pump is included.SS vacuum pipe & ball valve with KF25 adaptor generate 1E-2 torr vacuum. |

| Gas Flow Control System | Multiple-channel Gas Optional Control System with PLC Touchscreen is included.Three mobile carts are included to support the furnace and the revolving feed system. |

Water Chiller

| A 16L/min recirculating water chiller is included for cooling the flange.Short water power off and Over temperature alarm built in. |

| Dimensions | 2400mm(L) x 600mm(W) x 1300mm(H) |

| Warranty | One year limited warranty with lifetime support. |