Product Description:

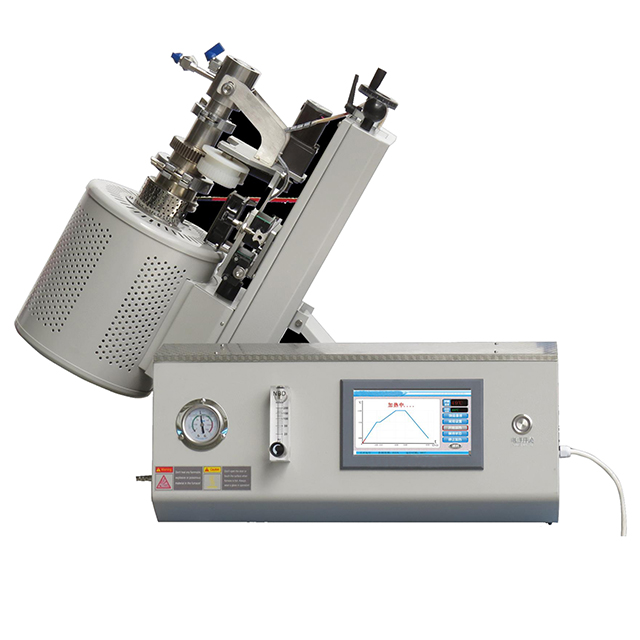

Automatic feeding and discharging vacuum gasification sintering furnace, the maximum temperature is 1200 ℃, stainless steel furnace tube. Equipped with two stainless steel augers with a pitch of 40mm and 60mm, different feeding speeds can be realized, and the uniformity of heating temperature and reaction uniformity of materials can be effectively improved.

The stainless steel vacuum feed tank has a volume of 4 liters, and the right side of the equipment is equipped with a stainless steel water-cooled discharge tank with a volume of 4 liters. The feeding tank is equipped with a vibrating motor to control the stability and uniformity of feeding. On the left side, the sprocket drives the auger in the furnace tube to rotate to realize the stable entry and exit of materials, and the rotation speed is adjustable.

The equipment has three temperature control units, and the length of the temperature zone is 600 mm. Through the quick installation design, the maintenance and replacement of the furnace tube and the auger are very convenient.

This equipment is mainly used in the heat-dissolving treatment of organic solid waste, and the continuous sintering experiment under vacuum or atmosphere.

Product Features:

1. The furnace tube is made of 310S heat-resistant stainless steel.

2. PLC centralized control is adopted to simplify operation, and it is equipped with a 7-inch touch screen for real-time display of various data, which is intuitive and clear;

3. It is equipped with an alarm function, which can realize unattended sintering;

4. It is equipped with a material level monitor to monitor the material condition, and it is also equipped with a vibrator to facilitate the introduction of materials.

5. High-purity Al2O3 fiber refractory insulation material has excellent insulation effect and effectively reduces the power consumption of equipment;

6. Adopt advanced and stable dynamic sealing system to ensure that the equipment can be used in vacuum and atmosphere;

7. The furnace body can be tilted at -14 ° (discharging) -2° (feeding), which is convenient for loading and unloading operations;

Technical parameters:

| Product number | KS-RT1000-80T-4L |

| Electrical Specifications | AC380V 7.5KW |

| Achievable temperature | 1200 C (<1 hour) |

| Working Temperature | under 1000C |

| Achievable heating rate | ≤ 20°C/min |

| Heating zone length | φ150×600mm |

| Furnace size | Length 1650×Depth 760×1720mm |

| Heating element | Mo doped Fe-Cr-Al alloy |

| Precautions for equipment use | When the furnace temperature of the equipment is ≥300°C, it is forbidden to open the furnace to avoid injury;

2. When the equipment is in use, the reading of the absolute pressure gauge should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure; 3. When used under vacuum, the operating temperature of the equipment shall not exceed 600°C. |

| service support | 1-year warranty with lifetime support (consumable parts such as furnace tubes and seals are not included in the warranty). |