Vicat Softening Temperature (Vicat Softening Temperature) is to put the thermoplastic in the liquid heat transfer medium,Under a certain load and a certain constant rate of temperature rise, the temperature when the sample is pressed into 1 mm by a 1 mm2 indenter. Vicat softening temperature is to evaluate the heat resistance of materials, reflecting the physical properties of products under heated conditions.

One of the indicators of mechanical properties. Although the Vicat softening temperature of the material cannot be directly used to evaluate the actual use temperature of the material, it can be used to guide the quality control of materials. The higher the Vicat softening temperature, the better the dimensional stability of the material when heated, and the smaller the thermal deformation.

That is, the better the thermal deformation resistance, the greater the rigidity and the higher the modulus.

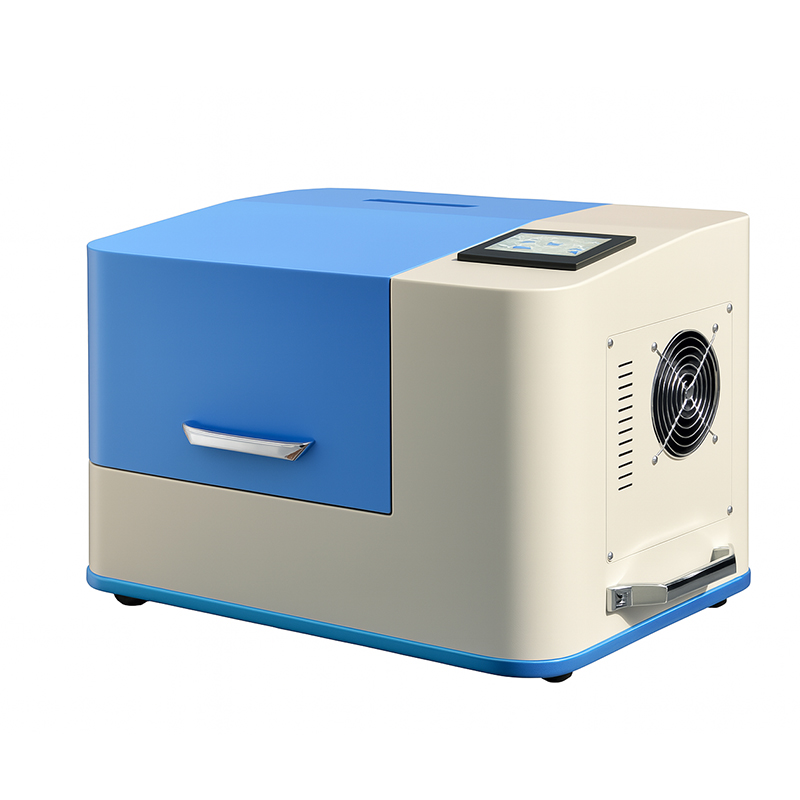

Technical parameters:

| Model | KS-GP-VCA300 |

| Temperature Range | Room-300℃ |

| Heating Rate | (120±10)℃/h; (12±1)℃/6min (50±5)℃/h ; (5±0.5)℃/6min |

| Temperature resolution | 0.1℃ |

| Temperature accuracy | ±0.5℃ |

| Maximum deformation indication error | ±0.001mm |

| Maximum deformation measurement range | 0-12mm |

| Number of sample racks | 3 pieces |

| Heating medium | Methyl silicone oil (generally choose 100 centistokes for kinematic viscosity) or transformer oil |

| Max Heating Power | 4 KW 16A |

| Cooling method | Air cooling above 150℃, water cooling below 150℃ |

| Load bar-level pallet quality | 68g |

| Dimension | 600mm×570mm×1300mm (3 stations) |

| Voltage | AC220V ±10 50HZ |