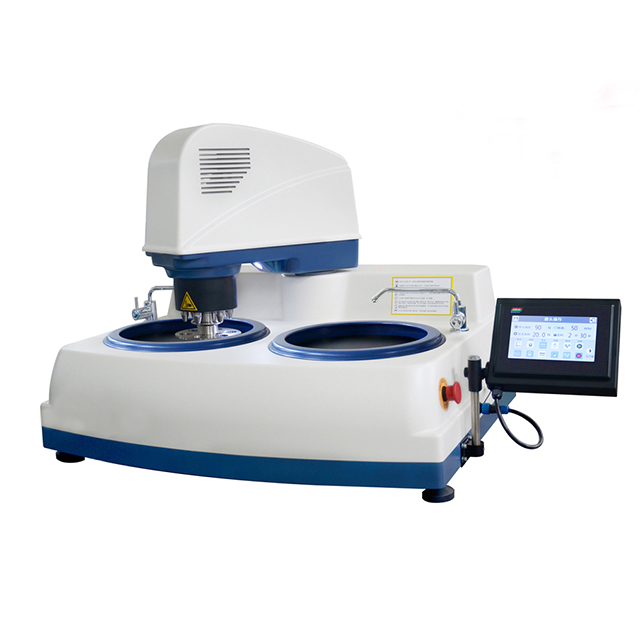

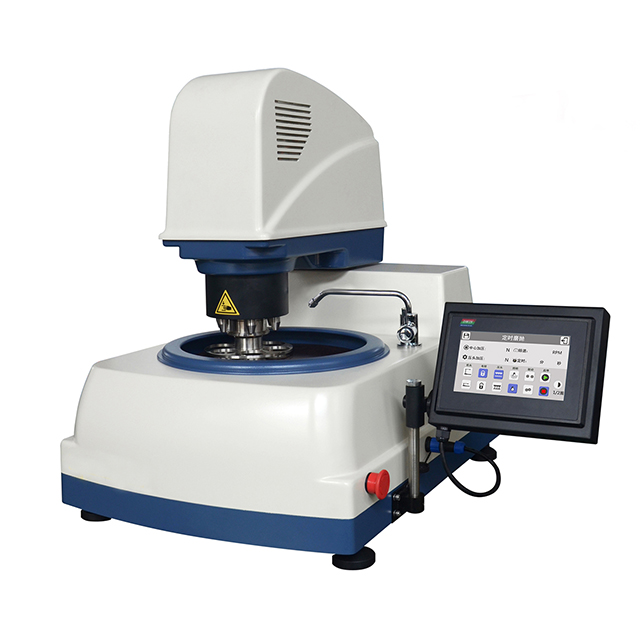

Product Description:

KS-GP-160D double-sided grinding and polishing machine is mainly used for double-sided precision grinding and polishing of quartz wafers, sapphire, ceramics, glass, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium and other crystals), metal and other sheet materials . This machine adopts a worm gear reducer as the transmission mechanism, and realizes the rotation of the upper, middle and lower shafts at different speeds and directions through gear sets, so that the upper and lower grinding and polishing discs and the middle sun gear produce speed differences and relative motions. The piece is placed in the inner hole of the sample-loading planetary gear driven by the sun gear, so that it can be ground and polished on both sides. The double-sided grinding and polishing machine can choose to use the grinding disc and abrasive to grind the sample, or choose the polishing disc to stick sandpaper to grind the sample. The polishing disc paste sandpaper is to paste the sandpaper on the polishing film and then adsorb the polishing film on the polishing disk for grinding and polishing. Multiple samples can be ground at the same time. The grinding and polishing efficiency is high, which is suitable for grinding a large number of samples or small batch production in factories.

Product Features:

1. The speed adopts the control method of manually adjusting the frequency of the inverter.

2. It can simultaneously perform double-sided grinding and polishing on 4 substrates with a maximum size of Ø2".

3. Double-sided thinning of thin sheets can be carried out.

4. It is an ideal tool for double-sided grinding and polishing of Si, Ge and oxide single crystal substrates.

Technical Parameter:

| Model | KS-GP-160D |

| Power supply | 220V 50Hz |

| Power | 550W |

| Grinding and polishing plate | Ø225mm |

| Grinding and polishing disk speed | steplessly adjustable within 0-72rpm |

| Maximum sample size | Ø50mm, thickness ≤15mm |

| Weight of upper grinding and polishing plate | 3.5kg |