Product Description:

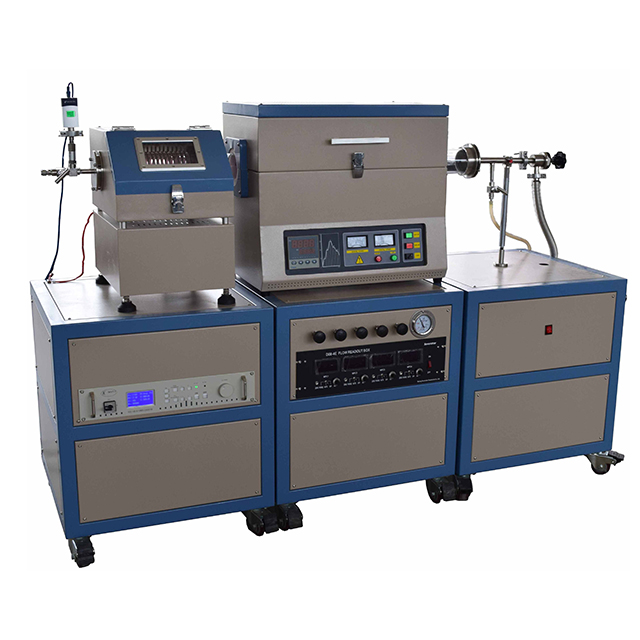

Parallel-plate capacitive PECVD is a technology that uses plasma to activate reactive gases to promote chemical reactions on the substrate surface or near-surface space to form solid films. The basic principle of plasma chemical vapor deposition technology is that under the action of high-frequency or DC electric field, the source gas is ionized to form plasma, using low-temperature plasma as the energy source, passing an appropriate amount of reaction gas, and using plasma discharge to activate the reaction gas And realize the technology of chemical vapor deposition. The system is a single-chamber plasma-enhanced chemical vapor deposition (PECVD) process development equipment for growing nanowires or using CVD to make various thin films is a new discovery tool.

Product Features:

1.The system adopts a single-tube structure, and the front door is opened manually.

2. Thin films are deposited in a high-vacuum environment.

3. Stainless steel cavity

4.The sample stage can be rotated.

5. Adopt the capacitive coupling method with the sample on the bottom and the sprinkler on the top

Technical Parameters:

| Product Model | KS-PECVD-300 |

| Power supply | 220V single phase 50±0.5 Hz or as customized |

| Power rate | less than 4Kw |

| Ambient temperature | 10℃~35℃ |

| Water supply | water pressure 0.2Mpa~0.4Mpa, water temperature 15 ℃ ~ 25 ℃ |

| Vacuum chamber size | Ø300×300mm |

| The ultimate vacuum degree | 8.0×10ˉ⁵Pa (with optional molecular pump after baking and degassing) |

| vacuum leak detection rate | ≤5.0x10-7Pa.l/S |

| The maximum heating temperature of the sample | 500°C |

| The temperature control accuracy | ±1°C |

| Spray head size | Φ90mm |

| RF power supply | frequency 13.56MHz, maximum power 300W automatic matching; |

| Gas type | 2 way with 100 SCCM controller or as customized |