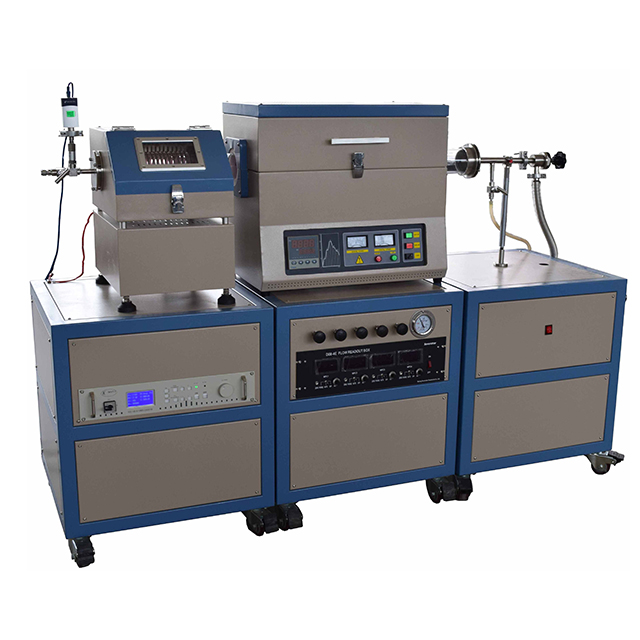

KS-MPCVD2060 Microwave Plasma Chemical Gas Phase Deposition (MPCVD) system is a multi-purpose, high-stable medium-pressure Microwave plasma (MPCVD) comprehensive processing equipment designed and developed for the specific requirements of users.It has advanced performance, perfect function, reasonable structure, convenient to use, safe and reliable, beautiful appearance, especially suitable for single crystal and polycrystal diamond film, diamond film chemical vapor deposition (CVD); material surface treatment and modification; low-temperature oxide growth and other fields.

Technical Parameters:

| 1) Microwave sources and systems |

| Operating frequency | 2,450 M H z point frequency |

| output power | 0.1~ 6kW Continuous adjustable4 |

| Power stability | 1% (@ Steady-state) |

| standard flange input power supply | 380VAC / 50Hz, three-phase and five-line |

| cooling water flow rate | 18 L/min |

| System resident wave coefficient | VSWR 1.5 |

| Microwave leakage | Compliance with national standards |

| 2)Microwave vacuum discharge cavity |

| Size and working mode | Φ 200*300 (H) TM |

| mode effective deposition area | Φ 50mm |

| Pressure control range | 0.5KPa~30KPa |

| Pressure control accuracy | ±15Pa |

| 3)productive power |

| crystal growth | Growth rate of 10-15 m / H, single round growth, thickness greater than or equal to 1.6mm single crystal mass,There are basically no defects to the naked eye |

| 4)vacuum and sub-atmospheric system |

| Breaking mode | Charge, enter, N2. |

| Limit vacuum degree | excel 5×10ˉ¹Pa |

| Vacuum leakage rate | ≤10-9Pa.m³/s , |

| voltage reise | 24-Hour average pressure rise is less than 1Pa / H 5) Gas mass flow system |

| control range | 2%-100%F.S., Entrance pressure is 0.2-0.3MPa |

| Gas type and measuring range | H2 (1SLM), CH4 (100SCCM), O2 (10SCCM), N2 (20SCCM) |

| 6) Sample table system |

| Sample table diameter | Φ 60 mm, |

| water-cooled structure; sample table adjustment range | 0~15 mm |

| Cinal plate adjustment range | 0~60 mm |

| 7) Base measurement |

| Temperature control range(infrared temperature measurement); | 600~1200℃ |

| temperature control accuracy | ± 5℃; |

| Control range of the constant temperature area | the temperature difference at each point of the molybdenum platform is 30℃ |

| 8)insulation resistance | ≥5MΩ |