Product Features:

1.1 Ensure an anaerobic working environment through a high-precision oxygen analyzer;

1.2. The material can fully contact with the reaction gas to the greatest extent in a stable and uniform temperature field in the special-shaped quartz chamber based on the rotating shimmy structure;

1.3. The unique suspended gas phase generator can maintain a horizontal and stable output while the working chamber is shaking;

1.4. Multi-channel mass flow controller can precisely control the gas flow;

1.5. High-tight connection technology ensures no leakage of flammable gases and toxic and harmful gases. High-sensitivity pressure sensors and solenoid valves can ensure that the pressure in the working chamber is always within the set range;

1.6. The flammable, explosive, toxic and harmful gas detector is linked with the equipment, which can obtain real-time data in time and take corresponding closing measures. At the same time, the two alarm devices will issue an early warning prompt when the set warning value is exceeded;

1.7. The exhaust gas discharged from the working chamber is harmlessly treated through the exhaust gas treatment tank.

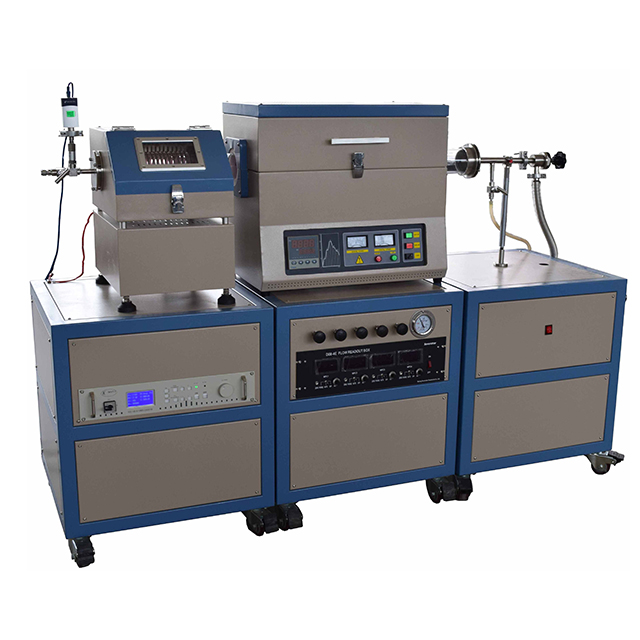

Technical Parameters:

| Product model | KS-CVD-T1200-150 |

| Votalge supply | 380V,3 phase |

| Power rate | 8KW |

| Heating element | K type |

| Max working temperature | ≤1100C |

| Temperature accuracy | ±1C |

| Heating zone size | Ø150×430mm |

| Furnace tube material | high purity quartz tube |

| Tube volume | 5L |

| Sample available space | 500mL |

| Tilt angle | -20 degrees (discharge) ~3 degrees (feed) |

| Furnace size | L1550mm×D830mm×H1360mm |

| Recommend Heating rate | 10C/min |