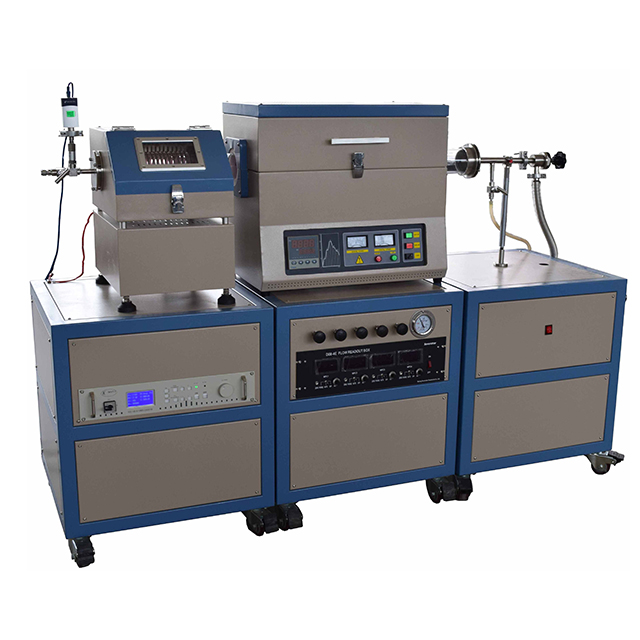

Product Description:

KS-LPCVD-1500 is a MIST/LPCVD

system designed for the epitaxial growth of thin films on various substrates up

to 1500°C heated by induction. It features an induction-heated graphite

substrate holder with precise PID control. The boron nitride (BN) shower head

enables a uniform deposition of precursors on a substrate at an elevated

temperature. The system also comes with a hermetic quartz chamber for LPCVD

without worries of precursor leaks. It is a unique tool for high-temperature

thin film growth, especially for next-generation semiconductors, such as Ga2O3

and BN.

Technical parameters:

| Product Model | KS-LPCVD-1500 |

| · Input voltage | three-phase 380±20% 50/60Hz |

| · Input power | 15KW |

| · Output current | 7-70A |

| · Oscillating frequency | 30-100KHZ |

| · Protection system | with water pressure, overheating, overpower protection |

| · Dimensions of the heating system | coil inner diameter Φ220mm, height 70mm, wound with Φ8 water-cooled copper tube, 4 turns |

| Cooling water requirements | water pressure ≥ 0.2Mpa water flow ≥ 6L/min; The temperature was set at 30°C. |

| Quartz furnace tube | Φ8.5”*500mm |

| Graphite sample stage | inner diameter φ155mm (6-inch substrate can be placed) |

| · Insulation material | graphite felt |

| · Maximum temperature | 1600℃<1h, long-term use at 1500℃ |

| · Recommended heating rate | ≤2℃/S |

| · Pressure gauge range | -0.1-0.15MPa |

| Gas-liquid mixing tank material | 316 stainless steel |

| · Volume of tank | 100ml |