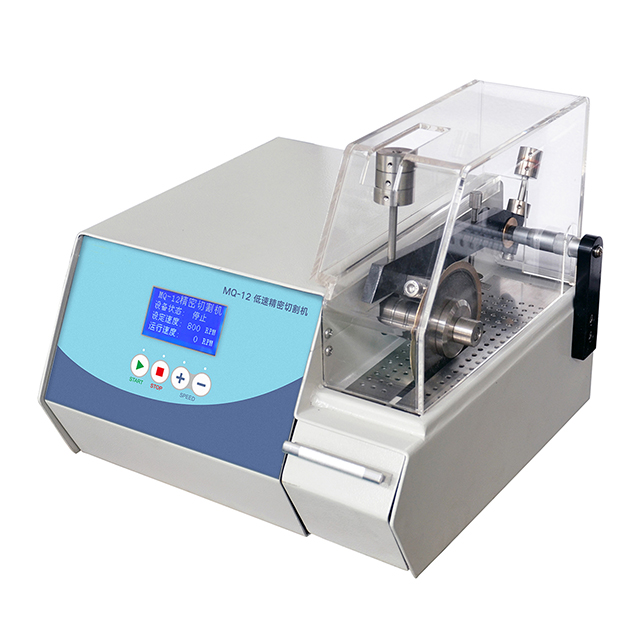

KS-STX-1203 Full automatic diamond wire cutting machine is suitable for cutting materials with different hardness, such as ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials. It is mainly used for valuable materials with large size, and the cut size can reach 12 ". KS-STX-1203 fully automatic diamond line cutting machine has high cutting accuracy, which can meet the cutting of most materials. Continuous cutting diamond line cutting machine, set the sample continuously after the cutting program is set, no manual adjustment is required. The size of the samples after cutting is high, within the range of ± 10 μm. Using a single -line cycle to recover the motion mode, the length of the line that can be available (≤150m), the long service life of one launch is greatly improved, which greatly improves the cutting efficiency. The thickness of the wire diameter can be adjusted. When the wire diameter is too thin, it can effectively protect the cutting line will not break due to the tight force. When a swing mechanism or a rotating swing mechanism Higher large samples. The machine is widely used. It can cut large samples or cut small samples. The design is exquisitely designed to largely meet the cutting requirements of most samples.

Main Features:

1. The main motor drives the diamond cutting line to move down the fixed speed, and the material is fixed on the workbench to ensure that the cutting is stable.

2. The workbench can be manually or through the program control 360˚ rotation adjustment.

3. Use the pneumatic tension system to use imported pneumatic elements to make the tension more stable and reliable.

4. The PLC program control system and large -size touch screen make the operation simple and fast.

| Power supply | 220V 50Hz |

| Power | <475W (max) |

| Spindle motor | AC frequency conversion motor, power 250W |

| Y, Z, R axis motor | precision stepper motor |

| control system |

| (1) In the manual control interface |

|

| Z axis speed setting range | 1~25mm/ min |

| Y-axis speed setting range | 1~100mm/min |

| R-axis speed setting range | 1~20º/min |

| Fine-tuning speed setting range | 1~20/min |

| (2) Automatic control interface |

| Y-axis travel | Y-axis feed length, setting range 0.01~300mm |

| Z-axis travel | Z-axis feed length, setting range 1~300mm |

| Cutting times setting range | 1~999 times |

| Cutting speed | Z-axis feed speed, setting range 0.05~40mm/min |

|

|

| Return speed | the speed of the Z axis back to the starting position, the setting range is 1~40mm/min |

| The wire transfer speed of the cutting line | 0-8m/s is adjustable, the digital display |

| The total length of the cutting line | ≤150m |

| The diameter of the cutting line | ≤0.45mm |

| Y-axis travel | ≤300mm, digital display |

| Z-axis travel | ≤300mm, digital display |

| Y, Z axis feeding indication accuracy | 0.01mm |

| Table rotation angle | 0-360°, resolution 0.01°, digital display |

| table repeat positioning accuracy | < 0.032° |

| cutting sample size | Ø300mm×300mm(max) |

| Tensioning system | pneumatic tensioning, tensioning air pressure adjustment range 0-1MPa |