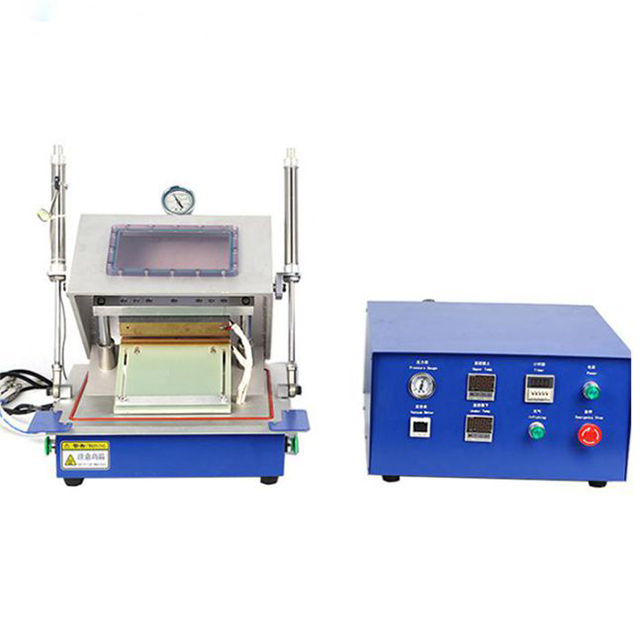

Product

Introduction

It is a

three-roller transfer coating equipment that can perform continuous and

intermittent coating, and is convenient for surface coating processes on

various substrates.

Functional Features

It can switch

freely to achieve continuous and intermittent coating;

Substrate tension

control, stable belt feeding, and equipped with a correction device;

Hot air oven, upper

and lower double-sided blowing, excellent drying effect;

Three-roller

transfer coating, with a wider coating window;

Scraper metering,

with precision adjustment mechanism, to obtain high coating accuracy;

OPLC control, touch

screen operation, convenient and easy to use; optional solvent recovery and

processing device;

Technical Parameters:

| Product name | Three-roll transfer intermittent type Pilot coating machine |

| Product model | KS-CDB-IPC330 |

| Coating method | intermittent coating, continuous coating |

| Roller width | 330mm |

| Coating width | Max300mm; customizable width |

| Mechanical speed | Max5 meters/min |

| Coating accuracy | ±3μm (edge green error ±5μm) |

| Coating thickness | Determined by slurry, 40~200μm |

| Thickness adjustment | Manual free adjustment |

| Rewinding and unwinding diameter | φ300mm |

| Rewinding accuracy | ±0.5mm |

| Tension control | Max60N (adjustable) |

| Micrometer display accuracy | lμm |

| Drying temperature | adjustable from room temperature to 120℃ |

| Drying unit | standard hot air drying |

| Oven length | three sections, 1.5M per section, 4.5M in total |

| Compressed air | 0.5~0.7Mpa |

| Power supply | three-phase 380V/50Hz |

| Maximum power | 30kW |

| Dimensions | L6600"W1200"H1600mm |

| Weight | about 2Ton |