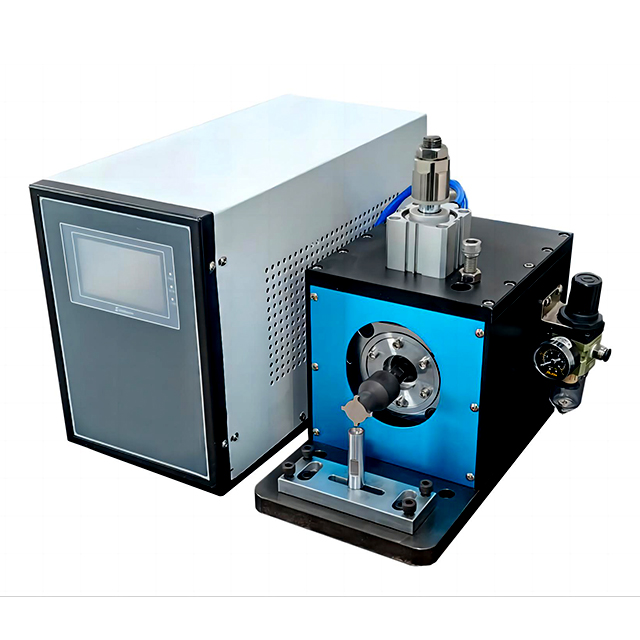

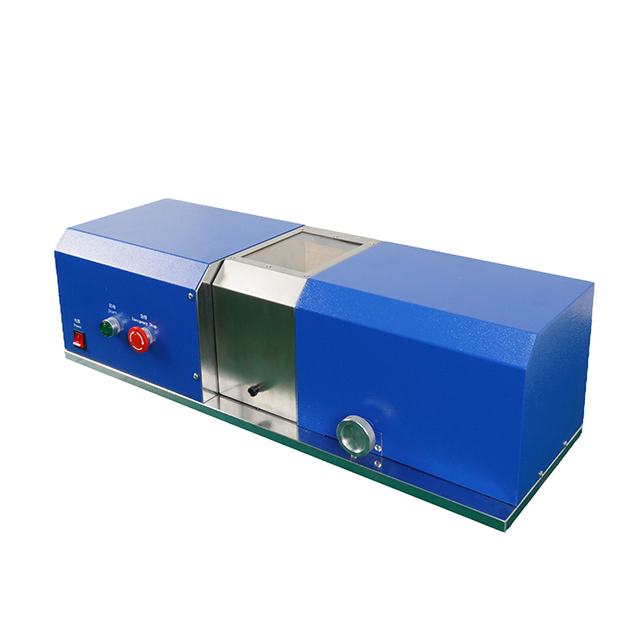

Product Introduction:It is suitable for the lamination process of battery cells, and the positive and negative electrode sheets are carried out with a separator Z Shaped lamination,It is a device that can be applied to the electrode lamination process of lithium-ion batteries. The equipment adopts the automatic tension control system of the separator membrane, and the cylinder drives the diaphragm to move left and right Z Glyph-shaped lamination, cantilevered design for easy operation. Compared with manual laminators, this equipment has the characteristics of high lamination efficiency, good lamination neatness, and a large range of battery sizes, making it an ideal choice for R&D sample production and small batch trial production equipment.

Main features:

* The adjustment, operation and maintenance of the machine are simple and easy;

* Applicable to a wide range of cell laminate sizes;

* Semi-automatic lamination, balance tension control system

* Automatic counting, zero function

* Function to automatically maintain the status of last used parameters after power failure and non-use

*The whole machine is suitable for a wide range of battery sizes

*Foot switch is used to control cylinder operation

* The adjustment, operation and maintenance of the machine are simple and easy

* High work efficiency, with digital display timer

* Tabletop type, can be placed on ordinary desktop, exquisite and beautiful appearance;

Technical Parameters:

| Model | KS-PCB-LSM200-B |

| Lamination accuracy | The uniformity is better than ±0.5mm |

| Lamination size (including tab length) | Min. L44mm*W44mm (need to replace the tablet) Max. L200mm*W150mm (tabs on the long side). |

| Lamination thickness | Max.12mm (if it is thicker, the adjustment plate needs to be replaced). |

| Diaphragm roll diameter | Max. 220mm |

| Installation dimensions | L512mm*W820mm*H580mm |

| weight | Approx. 50Kg |

| power supply | Voltage single-phase 220VAC±10% (customizable 110VAC), frequency 50Hz/60Hz, power 200W |

| Air source | 0.4~0.6MPa compressed air |

| Usage environment | It is recommended that the ambient temperature is 25±3 °C, the humidity is 30~90RH, and there is no vibration and electromagnetic interference |