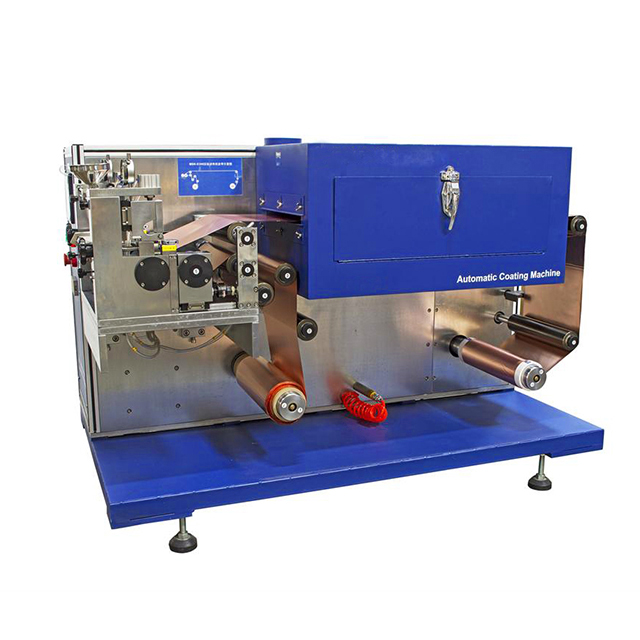

KS-PCB-RTC250 is a automatic battery electrode coating system with a compact footprint that is less than 6'x3'. It uses transfer coating technique for better coating uniformity and is perfect for research or building prototypes (e.g. pilot scale studies) of new generation rechargeable batteries. It is integrated with the functions/ features of metallic foil roll unwinding (reeling out), slurry holder, coating blade, baking oven, and final electrode winding (reeling in) together with touch screen operation for customer's the most convenience.

Technical Parameters:

| Working Voltage | 208 - 240 V AC, 50/60Hz, Single Phase |

| Max. Power Consumption | 4 KW ( 30A Air breaker required ) |

| Max.Coating Width | 250mm |

| Thickness adjustable range | 0-5mm |

| Coating thickness (after drying) | 30 - 200um (for most kinds of battery electrode coating material)

|

| Thickness Precision | ± 3µm (± 5µm at edges) |

| Coating Speed | 0-750 mm / minute |

| Max. Drying Temperature | 120°C

|

| Temperature Accuracy | ±1°C |

| Heating Zone Length | 710mm (28") |

| Reeling/Unreeling Shaft | 75mm (ID) |

| Max. Reeling/Unreeling Diameter | 250mm (OD) |

Max. Coating Length

| · Depending on the coating and substrate thickness.· |

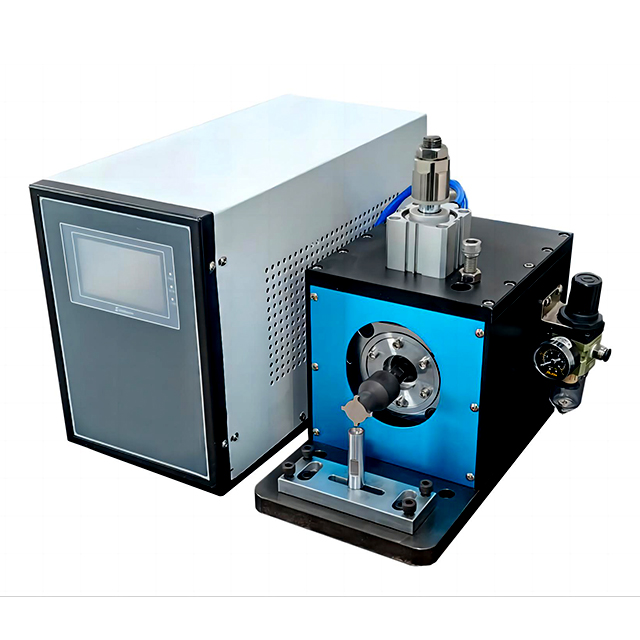

Slurry Stirring

| SS316 Moving Rod |

| Exhaust Port Size | 127mm O.D |

| Compressed Air | 0.5-0.8 MPa (Air compressor not included.)

|

| Product Dimensions | 1620mm ( L) x 950mm (W) x 1100mm (H) |

| Warranty | · One Year limited warranty with lifetime support· |

| Net Weight | 1000 kg (2200 lbs) |

| Shipping Dimension | 70" x 45" x 55" |