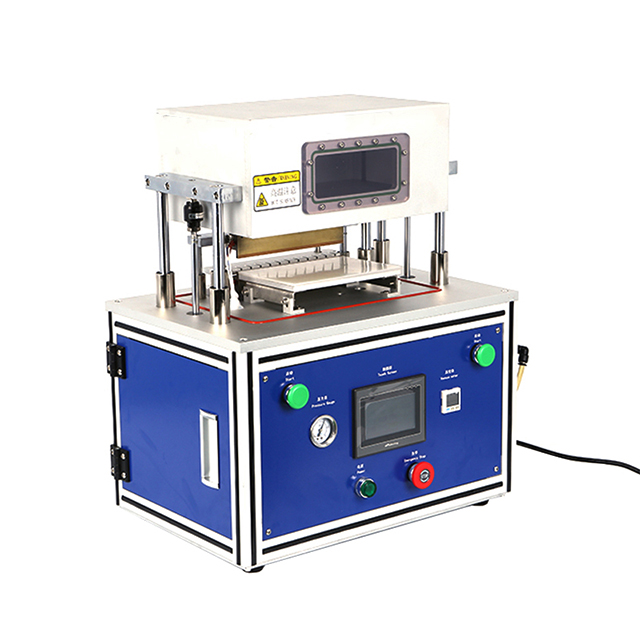

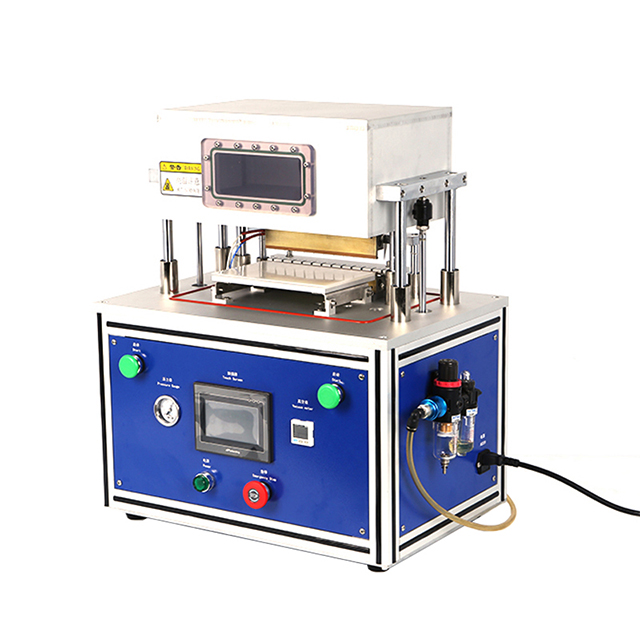

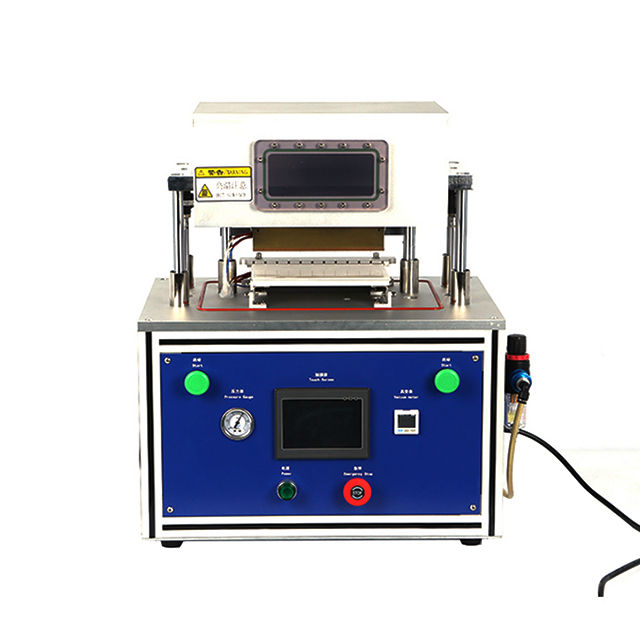

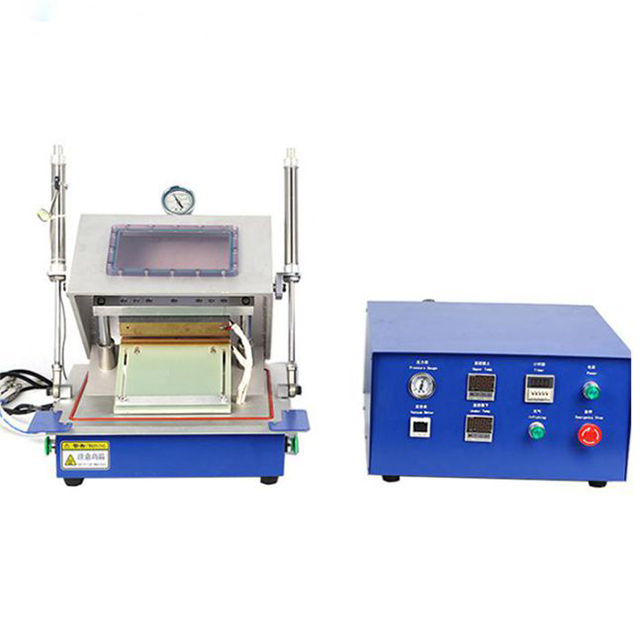

It is mainly used for incidental piercing and secondary vacuum final sealing of flexible packaging batteries. It is not recommended to use it in a glove box without special conditions, and it can achieve many functions such as vacuuming, piercing and draining, heating and sealing. The vacuum degree of the working chamber of the equipment is good, the sealing effect is high, and the finished battery is flat.

Features :

1. The head is made of copper material, which has good heat transfer effect, saves electricity consumption, improves work efficiency, and saves energy compared with similar products;

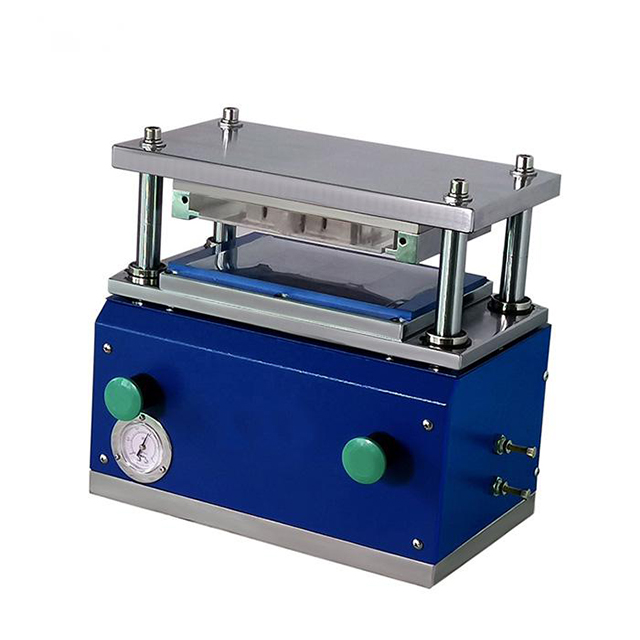

2. The pressure of the upper and lower heads can be adjusted by the pressure regulating valve to meet the requirements of different process parameters;

3. The upper and lower heads are driven by cylinders and guided by two linear guide sleeves, which can move up and down flexibly and accurately.

4. Ensure the parallelism requirements of the product after edge sealing;

5. With automatic puncture function;

6. The cover cavity is driven by an air cylinder and guided by a linear guide sleeve, which can move up and down flexibly, and the guidance is accurate to ensure the product tightness requirements;

7. It can be applied to different specifications of product batteries, and the adjustment is simple and convenient;

Technical Parameters:

| PO Vacuum Heat Sealing Machine KS-PCB-VHS200 |

| Chamber material | The chamber is made from Aluminum alloy, non-corrosive |

| Vacuum degree | ≤-95Kpa (Buyer prepare vacuum pump) |

| Sealing head temp | Room temp ~250℃. it’s adjustable |

| Temp accuracy | ±1.5℃ |

| Heat sealing pressure | 0~7Kg/cm2 (adjustable) |

| Heat sealing time | 0~99s adjustable |

| Sealing width | 5mm |

| Max sealing size | 200mm |

| Sealing head flatness | Test by triple carbon carbonless paper, set the head air pressure at 0.6MPa, the temperature at 200 degrees, the extrusion of the seal evenly |

| Air compressor working speed | ≥180 tims/h |

| Power | 300W heating pipe, the power consumption around 0.6KW when heating . |

| Power supply | 220V/50Hz |

| Power: 50W | 50W |

| Compressed air | 0.5~0.7Mpa |