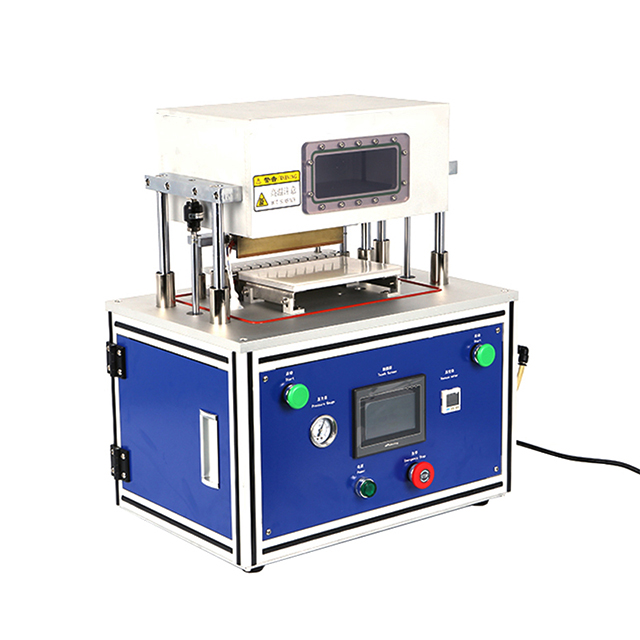

Product

Introduction·

Adopts two or more continuous slitting processes for roll

materials. The equipment is equipped with a precision knife seat, which can

achieve extremely high-precision foil slitting and is widely used in lithium

batteries, metal foils, optical films and other functional film industries.

Main

features·

*Ultrafine tungsten steel blade, good slitting quality, long

service life;

*High slitting width precision, no burrs, no waves, no

indentations in the finished product;

*Adjustable cutting amount, adjustable ratio of knife speed

to material linear speed;

*Adaptable to slitting of materials of different materials

and thickness values by adjusting the feeding and discharging angles;

*Single vertical plate structure, independent knife seat,

equipped with dust removal device;

*Upper and lower circular knife structure, slitting width

can be adjusted by replacing the spacer;

*Automatic control of winding tension, upper and lower axes

can be adjusted independently within 50N;

*PLC control, HMI operation, convenient and easy to use;

·Technical

parameters·

| Product name | Battery roll-to-roll continuous slitting machine |

| Product model | KS-CDB-RCS300 |

| Stripping method | single-piece rolling cutting |

| Cutter type | upper and lower circular cutters |

| Width adjustment | adjust by replacing the spacer |

| Cutting thickness | 10~300μm |

| Cutting accuracy | ±0.1mm |

| Stripping blade | ultra-fine particle alloy tungsten steel, diameter Φ100mm |

| Stripping width | adjustment range 20~230mm, customizable to 20~280mm |

| Burr condition | ≤25μm |

| Cutting amount | 0.2~0.4mm adjustable |

| Stripping speed | Max. 4m/min |

| Power supply | voltage single-phase 220VAC±10%, frequency 50Hz/60Hz, power 1kW |

| Use environment | recommended ambient temperature 25±3℃, humidity 30~90RH, no vibration and electromagnetic interference |

| Installation size | L900mm*W980mm*H450mm |